1. مقدمة لآلة مخروط الآيس كريم

ان آلة مخروط الآيس كريم هي آلة تصنيع أغذية متخصصة تنتج مخاريط الآيس كريم بكميات كبيرة وبجودة متسقة, مقاس, والملمس. يقوم بأتمتة العملية اليدوية التقليدية لصب الخليط, الخبز, تشكيل, والتبريد, تقليل تكاليف العمالة ووقت الإنتاج بشكل كبير.

أصبحت مخاريط الآيس كريم من الحلوى الأساسية على مستوى العالم, مع استهلاك المليارات كل عام. من صالات الآيس كريم الحرفية إلى الصناعية الكبيرة مصنعي مخروط الآيس كريم, الطلب على مخاريط الآيس كريم عالية الجودة لم يكن أعلى من أي وقت مضى. هذا الطلب يجعل آلة مخروط الآيس كريم استثمارًا أساسيًا للشركات التي تهدف إلى توسيع نطاق الإنتاج.

1.1 لماذا تحتاج الشركات إلى آلة مخروط الآيس كريم

- تناسق – حجم موحد, لون, وهشاشة.

- سرعة - إنتاجية عالية لتلبية فترات ذروة الطلب.

- كفاءة التكلفة – انخفاض تكاليف العمالة بالمقارنة مع الدرفلة اليدوية.

- صحة - هيكل من الفولاذ المقاوم للصدأ يضمن سلامة الغذاء.

2. التاريخ والتطور

إن رحلة مخاريط الآيس كريم من منتج جديد إلى منتج يتم إنتاجه بكميات كبيرة هي مثال رائع على الابتكار الغذائي.

2.1 إنتاج المخروط المبكر

في أوائل القرن العشرين, تم خبز المخاريط على شكل رقائق مسطحة ولفها يدويًا بسرعة قبل التبريد. يمكن للعمال المهرة أن يصنعوا فقط 200– 300 مخروط في الساعة, وكانت العملية غير متناسقة.

2.2 الميكنة

بحلول منتصف القرن العشرين, أجهزة المتداول الميكانيكية ظهرت. في حين لا تزال تتطلب صب الخليط اليدوي, أدت هذه الأجهزة إلى تسريع الإنتاج إلى حوالي 100000 جهاز 800– 1000 مخروط في الساعة.

2.3 الأتمتة الحديثة

اختراع ال ماكينة صنع الآيس كريم الأوتوماتيكية بالكامل في أواخر القرن العشرين أحدثت ثورة في إنتاج المخروط. آلات اليوم:

- قم بخبز ولف المخاريط تلقائيًا.

- يمكن أن تنتج ما يصل الى 12,000 المخاريط / ساعة.

- تشمل وحدات التحكم المنطقية القابلة للبرمجة (PLC) للدقة.

3. أنواع ماكينات صنع مخروط الآيس كريم

3.1 شبه تلقائي

- سكب الخليط يدويا.

- إزالة المخروط تتم بواسطة المشغل.

- مثالية للشركات الصغيرة ذات الطلب المرن.

3.2 أوتوماتيكية بالكامل

- تغذية الخليط, الخبز, المتداول, ويتم التبريد تلقائيا.

- يتطلب الحد الأدنى من العمالة.

- الأفضل للإنتاج التجاري بكميات كبيرة.

3.3 نوع الروتاري

- ترتيب دائري للقوالب.

- يضمن الدوران المستمر تسخينًا متساويًا.

- قدرة إنتاجية متوسطة إلى عالية.

3.4 نوع النفق

- تتحرك المخاريط عبر نفق ساخن للخبز والتشكيل.

- قدرة عالية للغاية (10,000– 12,000 قطعة/ساعة).

- يفضله المصنعون الصناعيون.

4. المعلمات الفنية لآلة مخروط الآيس كريم

| نموذج | سعة (جهاز كمبيوتر شخصى / ساعة) | أطباق الخبز | طريقة التدفئة | استهلاك الطاقة/الغاز | أبعاد (مم) | وزن (كجم) |

|---|---|---|---|---|---|---|

| IC-12S نصف آلي | 1,500 | 12 | كهربائي | 6 KW | 1400×800×1200 | 280 |

| IC-24A أوتوماتيكي | 3,000 | 24 | كهرباء / غاز | 8 KW / 2.5 م³ غاز/ساعة | 2200× 1200 × 1500 | 450 |

| IC-36R الروتاري | 6,000 | 36 | الغاز | 4 م³ غاز/ساعة | 3200×1800×1700 | 850 |

| نفق IC-60T | 12,000 | 60 | غاز / كهرباء | 5 متر مكعب من الغاز / ساعة أو 15 KW | 6000×2200×2000 | 1600 |

5. القدرة الإنتاجية والإخراج

إخراج ان آلة مخروط الآيس كريم يعتمد على:

- عدد أطباق الخبز – المزيد من اللوحات = إنتاج أعلى.

- طريقة التدفئة – نماذج الغاز تسخن بشكل أسرع من الكهرباء.

- وقت الدورة - تكمل معظم الآلات عملية الخبز خلال 90-120 ثانية.

- لزوجة الخليط – الاتساق الصحيح يمنع نقص الخبز.

مثال:

أ 36-آلة دوارة اللوحة تشغيل في 90 ثانية لكل دورة تنتج:

- 36 لوحات × 1 مخروط لكل لوحة × 40 دورات / ساعة = 1,440 المخاريط / ساعة (لكل خط دورة).

عند تشغيله باستخدام قوالب مزدوجة, يتضاعف الإنتاج إلى 2,880 المخاريط / ساعة.

6. كيف تعمل آلة مخروط الآيس كريم

خطوة 1: تحضير العجينة

دقيق, سكر, بيض, زيت, ويتم خلط النكهات في خليط ناعم. تؤثر درجة حرارة الخليط واللزوجة على هشاشة المخروط.

خطوة 2: تغذية الخليط

تقوم مضخات الخليط الأوتوماتيكية بتوزيع الخليط بالتساوي في القوالب.

خطوة 3: الخبز

تُخبز العجينة بين أطباق ساخنة حتى يصبح لونها بنياً ذهبياً.

خطوة 4: تشكيل

في حين لا تزال لينة, يتم لف الصفيحة المخبوزة في شكل مخروطي باستخدام قالب.

خطوة 5: تبريد

يتم تبريد المخاريط إلى درجة حرارة الغرفة للحفاظ على القرمشة.

خطوة 6: التراص والتعبئة والتغليف

يتم تكديس المخاريط النهائية تلقائيًا ونقلها إلى العبوة.

7. المواد وجودة البناء

يستخدم آلة موثوقة:

- إطارات من الفولاذ المقاوم للصدأ للنظافة ومقاومة التآكل.

- لوحات غير لاصقة مصنوعة من الحديد الزهر أو مطلية بالتفلون.

- أجزاء صالحة للطعام تلبية معايير ادارة الاغذية والعقاقير و CE.

8. كفاءة الطاقة والصيانة

- نماذج الغاز: تسخين أسرع, انخفاض تكاليف التشغيل للاستخدام بكميات كبيرة.

- نماذج كهربائية: أسهل في التثبيت, أفضل للإنتاج الصغير إلى المتوسط.

نصائح الصيانة:

- لوحات نظيفة يوميا.

- قم بتشحيم الأجزاء المتحركة أسبوعيًا.

- فحص مواقد الغاز أو العناصر الكهربائية شهريًا.

9. التطبيقات

- صالات الآيس كريم

- مصانع الحلويات المجمدة

- شاحنات الغذاء

- شركات التموين

10. المزايا

- جودة المنتج موحدة

- تقليل الاعتماد على العمل

- ارتفاع معدلات الإنتاج

- وفورات في التكاليف على المدى الطويل

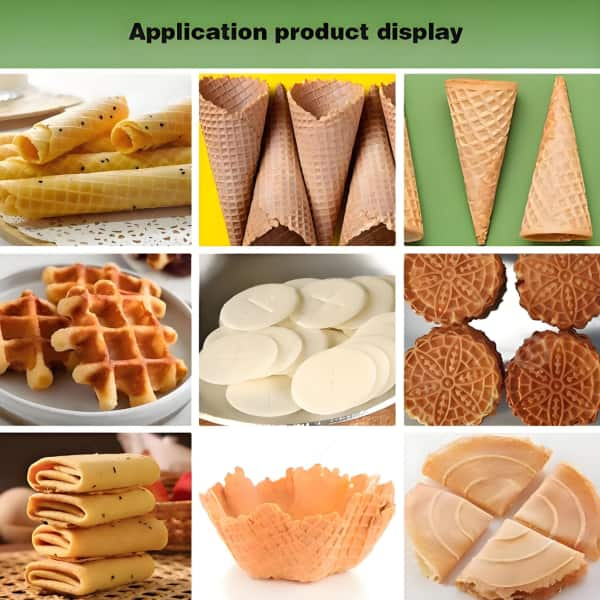

11. التخصيص

- ارتفاع المخروط وقطره

- أنماط محفورة

- مخاريط السكر, مخاريط الوافل, مخاريط الكأس

12. ضبط الجودة

- فحوصات منتظمة لدرجة حرارة اللوحة

- تحضير العجينة بشكل متواصل

- تخزين خالي من الرطوبة للأقماع

13. ميزات السلامة

- أزرار التوقف في حالات الطوارئ

- دروع الحماية من الحرارة

- الاغلاق التلقائي على ارتفاع درجة الحرارة

14. دليل الشراء

العوامل التي يجب مراعاتها:

- احتياجات الانتاج اليومية

- توافر المساحة

- فترة الميزانية وعائد الاستثمار

- مصدر الطاقة (غاز / كهرباء)

15. السعر والعائد على الاستثمار

- شبه تلقائي: $2,000– 5000 دولار

- السيارات الكاملة: $8,000– 15000 دولار

- نفق: $20,000– 50.000 دولار

مثال على عائد الاستثمار:

3,000 المخاريط / يوم × $0.20 الربح = 600 دولار يوميا

تكلفة الآلة = $10,000 → الاسترداد في ~ 17 يومًا.

16. تثبيت

- مستوي, أرضية مستقرة

- التهوية الكافية

- توصيل غاز أو كهرباء

17. استكشاف الأخطاء وإصلاحها

| مشكلة | سبب | يصلح |

|---|---|---|

| Underbaking | درجة حرارة منخفضة/الوقت | زيادة كليهما |

| لون غير متساوي | قضية انتشار الخليط | ضبط فوهة التغذية |

| المخاريط الشائكة | لوحات قذرة | تنظيف وإعادة طلاء |

18. أبرز الشركات المصنعة

- DT Food Machine Co., المحدودة - الصين

- هيبنسترايت – ألمانيا

- منتجات KVD Inter – هولندا

19. التعليمات

س: هل يمكنني عمل مخاريط السكر وأقماع الوافل على نفس الآلة؟?

أ: نعم, عن طريق تبديل القوالب.

س: ما هو عمر الآلة?

أ: 8– 10 سنوات مع الرعاية المناسبة.

20. خاتمة

ان آلة مخروط الآيس كريم إنها أكثر من مجرد معدات، إنها استثمار في كفاءة الإنتاج, اتساق المنتج, ونمو الأعمال. مع الآلة المناسبة, يمكن للشركات التوسع بسرعة, تلبية الطلب الموسمي, وتقديم مخاريط مثالية في كل مرة.

21. نظرة عامة على السوق العالمية لآلات مخروط الآيس كريم

يتوسع سوق مخروط الآيس كريم بشكل مطرد بسبب الشعبية العالمية للحلويات المجمدة. وفقا لتقارير الصناعة, ومن المتوقع أن تتجاوز مبيعات الآيس كريم العالمية $89 مليار دولار أمريكي بحلول 2028, مع الوجبات المخروطية التي تمتلك حصة كبيرة في السوق.

21.1 محركات النمو الرئيسية

- طفرات موسمية – فترات الصيف والأعياد تزيد المبيعات.

- الأسواق الناشئة – النمو السريع في آسيا, الشرق الأوسط, وأفريقيا.

- تنويع المنتجات – الإكثار من استخدام مخاريط الوافل الحرفية والأقماع الخالية من الغلوتين.

21.2 الطلب الإقليمي

- أمريكا الشمالية – ارتفاع الطلب على مخاريط الوافل المتميزة في المحلات التجارية الحرفية.

- أوروبا – تفضيل قوي للهش, مخاريط السكر منقوشة.

- آسيا والمحيط الهادئ – الاعتماد السريع على خطوط الإنتاج الآلي.

- الشرق الأوسط & أفريقيا – زراعة سلاسل الحلوى المجمدة.

22. وأوضح المعلمات التقنية التفصيلية

دعونا نحلل المعلمات الفنية من القسم 4 حتى يفهم المشترون تمامًا ما يعنيه كل منهم.

22.1 سعة (جهاز كمبيوتر شخصى / ساعة)

الحد الأقصى لعدد المخاريط التي يمكن للآلة إنتاجها في ساعة واحدة في ظل الظروف المثالية. هذا يتأثر:

- وقت الدورة (ثواني لكل خبز)

- عدد أطباق الخبز

- حجم المخروط

صيغة:

السعة = (أطباق الخبز × المخاريط لكل طبق) × (60 / وقت الدورة بالدقائق)

22.2 عدد أطباق الخبز

- تحتوي كل لوحة على تجويف القالب.

- المزيد من اللوحات = إنتاج أعلى, ولكن أيضًا مساحة أكبر للآلة.

22.3 طريقة التدفئة

- الغاز: التسخين المسبق بشكل أسرع, أفضل للدفعات الكبيرة.

- كهربائي: تركيب أسهل, أفضل للمساحات الصغيرة.

22.4 استهلاك الطاقة/الغاز

يشير إلى كمية الطاقة المستخدمة في الساعة. على سبيل المثال:

- 5 م³/ساعة غاز = 5 متر مكعب من الغاز في الساعة.

- 8 كيلوواط كهربائي = 8 كيلووات/ساعة لكل ساعة تشغيل.

22.5 أبعاد & وزن

- مهم للنقل, تثبيت, وتخطيط المساحة.

23. التصميم الهندسي ومبدأ العمل

تجمع آلة مخروط الآيس كريم الحديثة الهندسة الميكانيكية, التكنولوجيا الحرارية, و ضوابط الأتمتة.

المكونات الرئيسية:

- إطار – الفولاذ المقاوم للصدأ للنظافة.

- مجموعة أطباق الخبز – الحديد الزهر أو الألومنيوم مع طلاء غير لاصق.

- محرك الأقراص - تدوير أو تحريك القوالب.

- مضخة الخليط – يضمن تعبئة دقيقة.

- لوحة تحكم PLC – ضبط درجة الحرارة, وقت الخبز, ودورة.

- ناقل التبريد - إحضار المخاريط إلى درجة حرارة الغرفة.

- وحدة التراص – محاذاة المخاريط للتغليف.

24. دورة الإنتاج خطوة بخطوة بالتفصيل

منصة 1 – تحضير العجينة

- نسبة الدقيق:سكر:بيضة:يؤثر الزيت على هشاشة المخروط.

- تضمن الخلاطات الصناعية الحصول على عجينة خالية من الكتل.

منصة 2 - التغذية

- تقوم المضخة الأوتوماتيكية بحقن الخليط في القوالب بدقة ±1%.

منصة 3 - الخبز

- تسخين موحد بين الصفائح العلوية والسفلية.

- وتتراوح درجات الحرارة عادة بين 160-220 درجة مئوية.

منصة 4 - التشكيل

- تعمل الأذرع الهوائية على لف الصفائح المخبوزة حول قوالب مخروطية.

- يتم الاحتفاظ بالشكل حتى يبرد قليلاً.

منصة 5 - التبريد

- الناقلات المبردة بالهواء تمنع التكثيف.

منصة 6 - التراص

- تعمل أذرع الروبوت على محاذاة المخاريط عموديًا للتغليف.

25. جدول الصيانة المتقدم

| تكرار | مهمة | لماذا هو مهم |

|---|---|---|

| يوميًا | لوحات نظيفة ومغذيات الخليط | منع الالتصاق وحرق بقايا |

| أسبوعي | تشحيم الأجزاء المتحركة | تقليل التآكل |

| شهريا | فحص مواقد الغاز/عناصر التسخين | ضمان التدفئة حتى |

| ربع سنوية | معايرة أجهزة الاستشعار PLC | الحفاظ على دقة الخبز |

| سنوي | استبدال القوالب البالية | حافظ على تناسق الأشكال المخروطية |

26. استهلاك الطاقة وكفاءة التكلفة

حساب المثال:

آلة تعمل بالغاز تستهلك 4 م³/ساعة مع الغاز بسعر $0.80/م³:

4 × 0.80 = $3.20/ساعة تكلفة التشغيل.

إذا أنتجت الآلة 6,000 المخاريط / ساعة وينتج كل مخروط $0.20 ربح:

الإيرادات / الساعة = $1,200 → تكلفة الطاقة = فقط 0.26% من الإيرادات.

27. مشكلات الإنتاج الشائعة وإصلاحاتها

مشكلة: تنكسر المخاريط بسهولة

سبب: الكثير من الرطوبة في الخليط.

حل: تقليل محتوى الماء بنسبة 5-10%.

مشكلة: لون مخروطي غير متساوي

سبب: تسخين اللوحة بشكل غير متساو.

حل: تحقق من محاذاة الموقد أو اتصال عنصر التسخين.

مشكلة: المخاريط تلتصق بالألواح

سبب: طلاء اللوحة البالية.

حل: طلاء أو استبدال اللوحات.

28. دراسات الحالة في العالم الحقيقي

قضية 1: محل جيلاتو صغير

- آلة: نصف تلقائي 12 لوحة.

- الإخراج: 1,500 المخاريط / ساعة.

- العائد على الاستثمار: 3 شهور.

قضية 2: مصنع متوسط

- آلة: دوارة 36 لوحة.

- الإخراج: 6,000 المخاريط / ساعة.

- العائد على الاستثمار: 45 أيام.

قضية 3: مصنع صناعي

- آلة: نفق 60 لوحة.

- الإخراج: 12,000 المخاريط / ساعة.

- العائد على الاستثمار: 25 أيام.

29. تحليل التكلفة والعائد للشركات المختلفة

| حجم الأعمال | الآلة الموصى بها | استثمار | الناتج اليومي | فترة عائد الاستثمار |

|---|---|---|---|---|

| متجر صغير | شبه تلقائي 12 لوحات | $3,000 | 1,500 المخاريط | 3 شهور |

| مصنع متوسط | الروتاري 36 لوحات | $12,000 | 6,000 المخاريط | 45 أيام |

| نبات كبير | نفق 60 لوحات | $35,000 | 12,000 المخاريط | 25 أيام |

30. نصائح لاختيار الموردين

عند اختيار المورد:

- التحقق من الشهادات (م, ISO, امتثال إدارة الغذاء والدواء).

- طلب عرض فيديو.

- اسأل عن توفر قطع الغيار.

- ضمان دعم خدمة ما بعد البيع.

31. لماذا تختار شركة DT Food Machine Co., المحدودة

- 20+ سنوات من الخبرة في الآلات الغذائية.

- المنشآت العالمية في 40+ بلدان.

- تصاميم قوالب مخصصة.

- الدعم الفني الكامل.

32. الأفكار النهائية

ان آلة مخروط الآيس كريم يمكن أن يكون أحد الاستثمارات الأكثر ربحية في مجال الحلوى. بقدرات إنتاجية تتراوح من 1,500 ل 12,000 المخاريط / ساعة, توفر هذه الآلات قابلية التوسع, تناسق, والكفاءة.