Complete guide to design and set up a yogurt machine and Industrial Yogurt Production Line

Introduction to the industrial yogurt business

Yogurt consumption has grown up in a sustained way, promoted by the demand for healthy foods, functional and with high nutritional value. Starting a yogurt business requires not only to understand the market and consumer preferences, but also to know the Technology behind the machine to make yogurt.

In this article, as yogurt machine manufacturers, We will explain step by step how it is designed, Build and mount a yogurt production line, From the treatment of milk to the final packaging.

1. What is a yogurt machine?

A yogurt machine It is a equipment designed to transform fresh milk into yogurt through controlled fermentation processes. At an industrial level, It is not a single machine, but of a set of interconnected equipment that allow:

- Pasteurize milk.

- Homogenize and standardize raw material.

- Inoculate lactic ferments.

- Ferment in specific conditions of time and temperature.

- Cool, store and package the product.

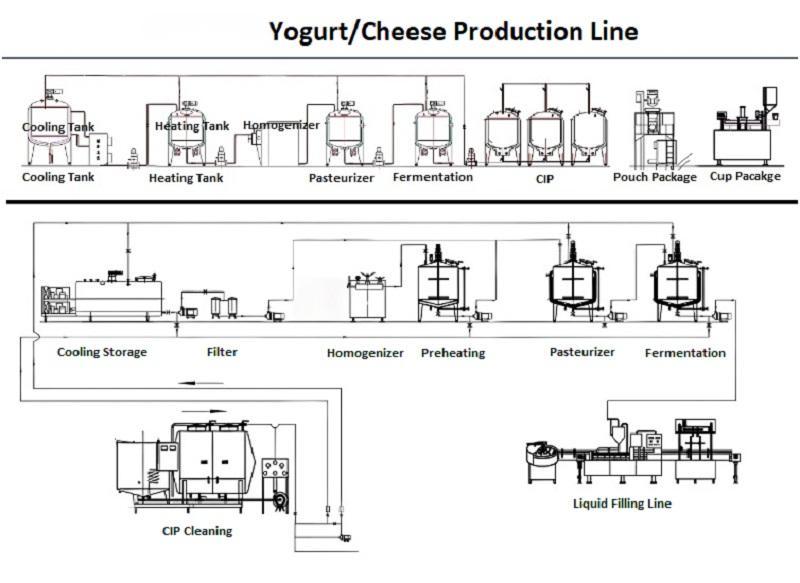

2. Main components of a yogurt production line

Design and build a yogurt production line It implies combining several machines in a logical sequence.

2.1 Milk reception tank

Receive fresh milk and store it hygienically. It usually includes cooling systems to avoid bacterial proliferation.

2.2 Pasteurization system

Pasteurization is key to eliminating undesirable microorganisms. Heat or pipe heat exchangers are used, that raise the temperature of the milk to 85-95 ° C for a few seconds.

2.3 Homogenizing

The homogenizer breaks the fat blood cells and ensures a uniform texture in yogurt.

2.4 Yogurt fermentation tank

Magic occurs here: Milk is mixed with lactic ferments (Lactobacillus bulgaricus y Streptococcus thermophilus) And it remains at 42-45 ° C during 4 a 6 hours.

2.5 Cooling system

After fermentation, Yogurt must quickly cool 4 ° C to stop bacterial growth.

2.6 Filling and sealing machine

Yogurt is packaged in jars, vessel, bottles or sachetts, According to the target market.

2.7 CIP Cleaning System

A system of Cleaning on site (CIP) guarantees that the entire line is kept free of waste and bacteria.

3. Design of a yogurt machine

The design depends on the Production scale and of customer requirements.

3.1 Production scale

- Small scale (50-200 L/h): Ideal for entrepreneurs or dairy farms.

- Median scale (500-1000 L/h): Suitable for regional factories.

- Large scale (2000 L/h onwards): Great trademarks oriented.

3.2 Construction materials

Stainless steel degree food (AISI 304 o 316) It is the most used for its corrosion resistance and easy cleaning.

3.3 Automation

Machines can be designed with control manual, semi -automatic or totally automatic, depending on the budget and the required efficiency.

4. How to set up a yogurt production line step by step?

Paso 1: Define the capacity and the target market

Before buying equipment, The estimated demand must be calculated, The type of yogurt (natural, Greek, bebible, With fruits) and packaging format.

Paso 2: SELECTION OF THE MACHINE TO MAKE YOGUR

Choose appropriate equipment according to the desired capacity and automation.

Paso 3: Plant installation

A hygienic space is required, With adequate water distribution, electricity, steam and compressed air.

Paso 4: Equipment and connection

The tanks, pipes and valves must be installed following sanitary regulations.

Paso 5: Pilot test

Before mass production, A test run is recommended to adjust parameters.

Paso 6: Staff training

Staff must know the use of the machine, Cleaning routines and quality controls.

5. Technical parameters of a yogurt machine

| Equipment | Ability (L/h) | Working temperature | Power (kW) | Material | Automation level |

|---|---|---|---|---|---|

| Reception tank | 200 – 2000 | 4 °C | 2 – 5 | Stainless steel | Manual / automatic |

| Pasteurizer | 200 – 3000 | 85 – 95 °C | 5 – 15 | Stainless steel | Automatic |

| Homogenizing | 200 – 3000 | 55 – 65 °C | 7 – 20 | Stainless steel | Automatic |

| Fermentation tank | 200 – 2000 | 42 – 45 °C | 4 – 10 | Stainless steel | Semiautomatic / auto |

| Cooling system | 200 – 2000 | 4 °C | 3 – 8 | Stainless steel | Automatic |

| Filling and sealing machine | 1000 – 5000 U/h | 4 °C | 5 – 12 | Stainless steel | Automatic |

6. Benefits of investing in a yogurt machine

- Quality control: guarantees food security.

- Production efficiency: Reduces times and costs.

- Flexibility: allows you to manufacture different types of yogurt.

- Scalability: You can start on a small scale and grow.

7. Frequent customers questions about yogurt machines

How much does a machine make to make industrial yogurt?

The price varies according to the capacity and level of automation, from 5,000 USD in small models up to more than 100,000 USD in full lines.

What space is needed to install a yogurt plant?

A minimum area of 50 a 100 m² for small production; more than 300 m² in industrial productions.

What raw material is needed?

Fresh milk or reconstituted powdered milk, lactic crops and, optionally, fruits or sweeteners.

Can Greek or drinkable yogurt produce with the same machine?

Yeah, With slight adjustments in filtering, Viscosity and packaging.

8. Tips for entrepreneurs who start a yogurt business

- Perform a Market analysis Before investing.

- Start with one modular production line That can grow.

- Prioritize Ferment quality and milk.

- Fulfill them local and international health regulations.

Yogurt machine

Build one yogurt machine and setting up an industrial production line is a viable and profitable project, provided that the appropriate equipment is chosen, a hygienic plant is designed and staff are trained. As specialized manufacturers, We offer personalized solutions for entrepreneurs and companies that wish to enter the yogurt market with high quality and performance equipment.