If you are thinking about producing ice cream wafers or cones professionally, you have probably asked yourself: What is the ideal cone recipe for a waffle maker?? This is a very common question among entrepreneurs., ice cream makers, and businesses that want to make their own crunchy cones, fresh and high quality.

In this we will explain step by step the wafer recipe, the exact ingredients, how to prepare the mixture, how to use a wafer maker, and also technical tips to improve texture, cone color and flavor. Besides, We will show you what type of industrial machines are used today to produce cones automatically or semi-automatically..

🍦 1. Introduction to the art of making wafers

The ice cream cone or wafer is a classic product in the dessert industry.. Its crispy texture, slightly sweet flavor and vanilla aroma make it the perfect complement to any type of ice cream.

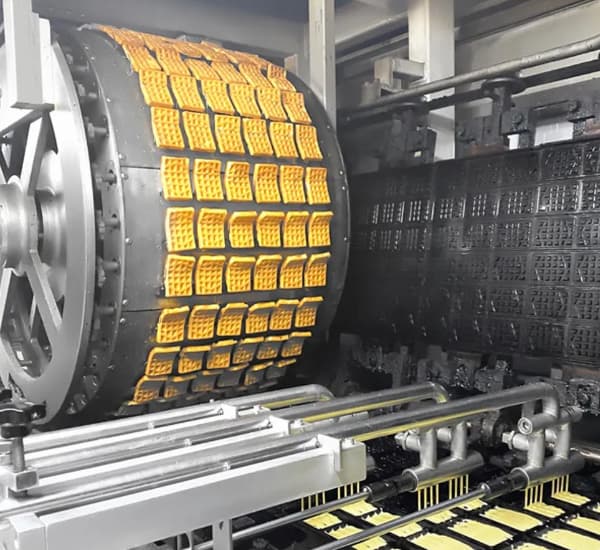

Nowadays, The cones are not only made by hand, but also through automatic wafer making machines, capable of producing thousands of units per hour with consistent quality and precise cooking control.

🧁 2. Basic ingredients for the wafer cone recipe

Next, we present to you the traditional industrial wafer recipe, used in factories and automatic production lines.

Ingredients per batch (for approximately 100 cones):

| ingredients | Approximate quantity | Function |

|---|---|---|

| wheat flour | 1 kg | Structural base of the wafer |

| Sugar | 400 g | Sweetness and golden color |

| Vegetable oil or butter | 200 g | Improves flavor and texture |

| Eggs | 6 units | Provides elasticity and cohesion |

| Water or milk | 1 liter | Adjust the viscosity |

| vanilla essence | 10 ml | Aroma and flavor |

| Room nice | 3 g | Balances the flavor |

| baking powder (optional) | 5 g | Improves porosity |

🥣 3. How to prepare the mixture correctly

- Mix the dry ingredients:

In a large container, combine the flour, sugar, salt and baking powder (if used). - Add the liquids:

Add the eggs, oil or melted butter, water or milk and vanilla essence. - Beat until you obtain a homogeneous mixture:

Use an industrial mixer or continuous mixer to avoid lumps. The texture should be liquid but slightly thick, similar to pancake batter. - Dough rest:

Let the mixture rest for 15–30 minutes so that the ingredients are completely integrated.. This improves the elasticity of the wafer when cooked..

⚙️ 4. How a wafer maker works

A wafer making machine It is the heart of the production process. These machines can be manuals, semi-automatic or fully automatic, and its main function is cook the dough at high temperature until you obtain a crispy sheet that is then rolled into a cone shape.

Main components:

- Heated cooking plates (electric or gas)

- Mass feed system (manual or automatic)

- Rolled system (manual, mechanical or pneumatic)

- Cooking time and temperature controller

- Interchangeable molds depending on the size of the cone

🧇 5. Step-by-step cooking process

- Machine warm-up:

Make sure the plates reach a temperature between 160 °C y 180 °C. - Pouring the dough:

In automatic machines, The dispenser distributes the exact amount of mixture onto each mold. - Cooking:

The dough is baked between 1 y 2 minutes, until achieving a uniform golden color. - Rolled:

The hot sheet is immediately rolled into a conical mold. In automatic machines, This is done with rotating metal cylinders. - Cooling:

The cones are cooled naturally or through a forced ventilation system, which guarantees its crispy texture.

🏭 6. Industrial production of wafers

In industrial production, The steps are integrated into an automatic manufacturing line, which can include:

- Automatic mixing system

- Continuous dough feeder

- Rotating or tunnel horn (gas or electric)

- Automatic cone winding

- Cooled on conveyor belt

- Classification, automatic counting and packing

Production capacity:

| Model | Ability | Heat source | Automation level |

|---|---|---|---|

| Small model (semi) | 50–1000 cones/h | Electric | Manual / Semi |

| Medium model | 1000–3000 cones/h | Gas / Electric | Semi / Automatic |

| Large model (industrial) | 5000–10000 cones/h | Gas | Fully automatic |

🍯 7. Technical tips to obtain perfect cones

- Control the viscosity of the dough: If it is too thick, the wafer will be hard; if it is very liquid, will break easily.

- Maintain a constant temperature: Variations in temperature can cause differences in color and texture.

- Clean plates regularly: Leftover dough can burn and affect the flavor of the product..

- Use fresh ingredients: Especially eggs and flour, that influence elasticity.

- Try different cooking times: Adjust color and crunch based on your target market.

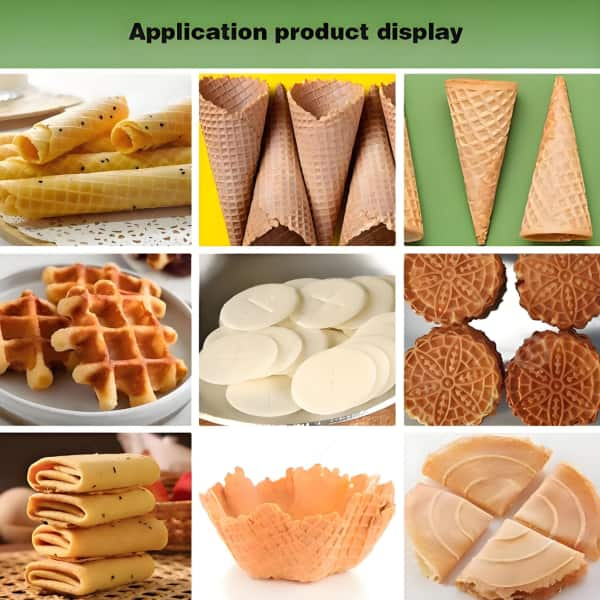

🔍 8. Differences between cones and flat wafers

- Ice Cooler: It has a conical shape, It is used to serve scoop or soft ice cream..

- Flat ship: Used as decoration or wrapping for desserts (For example, wafer rolls).

Both can be made with the same machine by changing the baking mold.

💡 9. Types of machines available on the market

| Machine type | Production level | Energy source | Approximate price |

|---|---|---|---|

| Manual | 50–200 cones/h | Electric | From 800 USD |

| Semi -automatic | 500–2000 cones/h | Gas / Electric | 5,000–10,000 USD |

| Automatic | 3000–10000 cones/h | Gas | 15,000–45,000 USD |

Las automatic machines They are the most recommended for ice cream factories or companies that seek to produce in volume., with uniform quality and lower labor costs.

🧾 10. Costs and estimated investment

When considering the investment, must be taken into account:

- Machine cost

- Raw materials cost (flour, sugar, oil, eggs, vanishing)

- Energy (gas or electricity)

- Preventive maintenance

- Production space

A small factory can be started with an investment between $5,000 y $10,000 USD, while a complete automatic line can exceed the $40,000 USD, depending on capacity and manufacturer brand.

🚀 11. Tips for starting the wafer business

- Analyze your local market: Ice cream cones are a seasonal product, but its consumption grows every year.

- Offers variety: Classic cones, Mini Cones, chocolate dipped cones or filled wafers.

- Take care of the presentation: Attractive packaging increases perceived value.

- Invest in a good machine: Product consistency is key to customer loyalty.

- Optimize energy consumption: Gas machines are usually more efficient in continuous production.

🎯 12. What is the recipe for the cone waffle maker??

The cone recipe for wafer machine it's simple, but success depends on the precision of the process, the quality of the ingredients and the efficiency of the machine used.

With a balanced mix of flour, sugar, eggs and oil, along with a reliable automatic cooking machine, you will be able to produce uniform cones, crispy and with an irresistible flavor.

Invest in one wafer making machine not only improves productivity, but also allows us to create a competitive and profitable product for the current ice cream market..