1. Panorama of the sector

The ice cream industry has established itself as one of the most dynamic within the food and beverage sector. In particular, Cone consumption has maintained sustained growth due to its practicality, Attractive presentation and universal acceptance in different markets. To supply this growing demand, It is essential to have high performance industrial equipment, And in this context, The figure of Machine manufacturer for ice cream cones acquire a strategic role.

Specialized manufacturers provide solutions that allow to produce cones in a standardized way, guaranteeing uniformity, hygiene and efficiency in mass production.

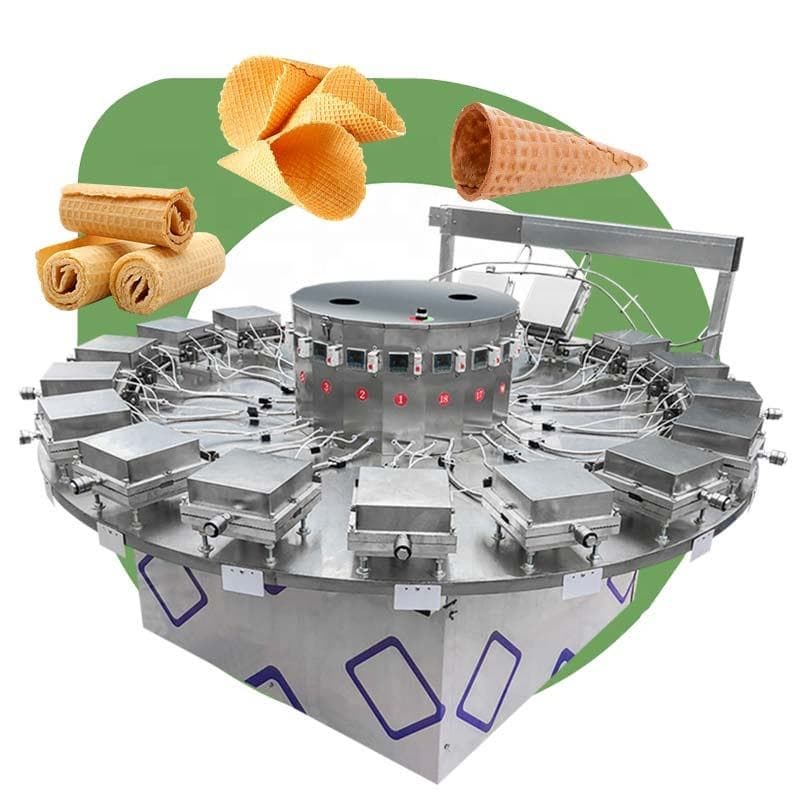

2. Team definition

The ice cream cones It is a system designed to convert a mixture of ingredients into crispy cones of different sizes and shapes. The process combines heat, Specific pressure and molds to give the final product its characteristic conical shape and crispy texture.

He Machine manufacturer for ice cream cones offers different types of equipment:

- Semi -utomatics, thought for small productions.

- Automatic, destined for medium and large factories.

- Complete production lines, that integrate mixed, baked, Rolled, cooled and stacked.

3. Main components

Industrial machines of this type usually incorporate several technical modules:

- Mixing system - Manager of homogenizing flour, agua, Sugar and other ingredients.

- Baked plates - Heating elements that cook the mass.

- Interchangeable molds - They allow to manufacture cones of different measures.

- Rolled device - It gives conical shape to the barquillo.

- Cooling transporter - It hardens the cone and maintains its crispy texture.

- Automatic stacker - Organize the finished product for packaging.

4. Reference Technical Specifications

| Model | Ability (Cones/hour) | Power (kW) | Mold | Type of control | Dimensions (mm) |

|---|---|---|---|---|---|

| DT-12 | 1200 – 1500 | 3.5 | 12 | Semiautomatic | 1200×900×1400 |

| DT-24 | 2500 – 3000 | 6.5 | 24 | Automatic | 2200×1200×1700 |

| DT-36 | 4000 – 4500 | 8.5 | 36 | Advanced PLC | 2600×1400×1800 |

| DT-48 | 5000 – 6000 | 10.5 | 48 | PLC + screen | 3000×1500×2000 |

Manufacturers also offer customization options: Logo engraving on the cone, diameter settings, Special molds for miniature cones or flat boats.

5. Advantages of machinery

The work of a Machine manufacturer for ice cream cones It focuses on guaranteeing key benefits for the end user:

- High productivity With continuous processes.

- Homogeneity in the quality of each cone.

- Resource optimization Thanks to automation.

- Hygienic design, Manufactured in stainless steel grade degree.

- Compatibility With traditional recipes, vegan or gluten.

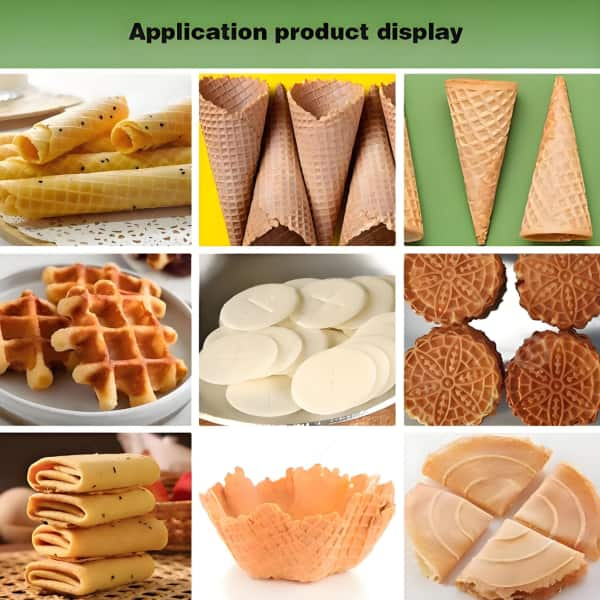

6. INDUSTRY APPLICATIONS

The machines are used in:

- Industrial ice cream plants.

- Confectionery and Bakery Factories.

- Bakery products exporting companies.

- Franchises and ice cream chains.

7. MAINTENANCE AND OPERATION

He Machine manufacturer for ice cream cones recommends a preventive maintenance plan to prolong the useful life of the equipment:

- Daily cleaning of plates and molds.

- Monthly insistence or burners inspection.

- Periodic replacement of pieces under wear.

- Lubrication of mobile mechanisms.

Advanced models include PLC controls and touch screens that facilitate operation and reduce errors.

8. Technological innovation

The most outstanding trends in the sector include:

- Energy efficiency in heating systems.

- Digital automation With remote monitoring.

- Versatility in molds To adapt the product to the market.

- Compatibility with alternative ingredients For consumers with special needs.

9. Global Market Perspective

The ice cream cones market experiences an estimated annual growth of 5%. Latin America countries, Asia and the Middle East are the main export destinations of machinery. The manufacturers' work is aimed at offering high capacity equipment with competitive prices, Responding to the growing international demand.

10. Manufacturer's choice factors

Before selecting a machine, It is necessary to consider:

- Real production capacity.

- Availability of technical service and spare parts.

- International quality certifications (ISO, CE, FDA).

- Post of personalization in molds.

- Extended guarantee and after -sales support.

11. Future projection

Diversification in cones types (integral, Chocolate coated, Mini Cones) and the tendency towards healthy foods force manufacturers to develop more versatile machines. He Machine manufacturer for ice cream cones It plays a crucial role by providing the team with equipment capable of adapting to these new market demands.

12. Conclusion

He Machine manufacturer for ice cream cones Not only does it provide technology, but also the ability to transform small businesses into competitive industrial operations. The standardization, Efficiency and innovation are key factors that determine success in the production of ice cream cones.

In this scenario, the DT Food Machine Company It is positioned as one of the suppliers that meet these international standards, offering reliable equipment and solutions adapted to different production needs.