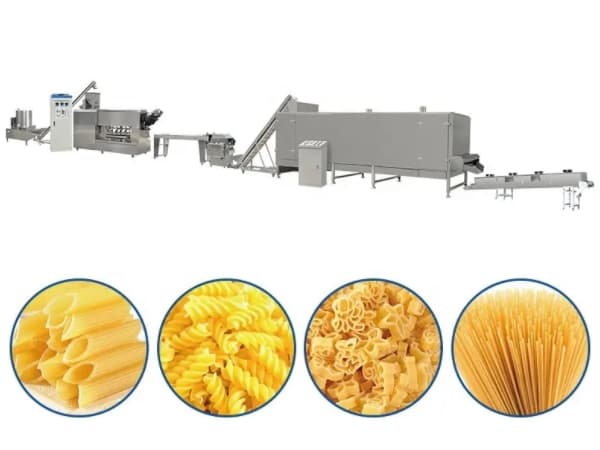

Pasta is one of the most consumed foods in the world. From the classic spaghettis to the sophisticated stuffed pasta, Its industrial production requires specialized and efficient equipment. A Machine line for pasta production Not only allows market demand to be satisfied, but also guarantees quality, Homogeneity and food security.

Next, We will explore in detail the key components, benefits, and types of production lines that make up this food industry in constant evolution.

Automatic pasta manufacturing line: Continuous production and without interruptions

A Automatic pasta manufacturing line It allows to produce large volumes of dry or fresh pasta without the need for constant manual intervention. This type of line includes automated mixed systems, extrusion, court, Drying and packaging.

Main advantages:

- Reduction of the operational cost.

- Greater consistency in product quality.

- Less human intervention, which minimizes error and the risk of pollution.

- Possibility of customizing formats, thicknesses and recipes.

These lines are ideal for large food or brand factories that distribute nationally and internationally.

Industrial equipment for paste: essential components

The Machine line for pasta production It consists of several Industrial equipment for paste, each with a key function in the process:

- Ingredient mixer: Mix the flour, agua, Eggs or other additives until you get a homogeneous mass.

- Kneader: gives the appropriate texture to the mass, airing it and giving it elasticity.

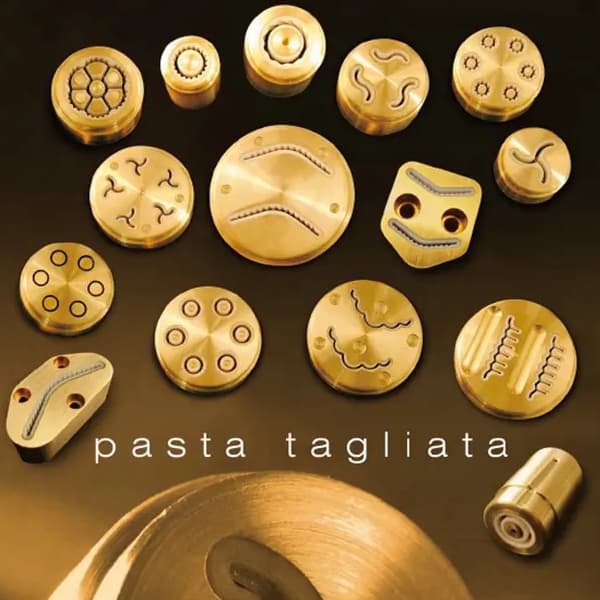

- Folder extruder: Form the pasta by interchangeable molds (penne, spaghetti, fusilli, etc.).

- Automatic cutter: regulates length according to the type of pasta.

- PRE-SEADOR The Dry Tunnel: Eliminates excess moisture.

- Cooler: Stabilize pasta before packaging.

- Automatic packaging: The process for commercial distribution ends.

Full plant for dry pasta production

A Full plant for dry pasta production includes all the necessary machinery to produce long -term paste, Ideal for export or retail sale. These plants are designed to operate 24/7 With minimal supervision.

Common characteristics:

- Production capacity from 250 until 3000 kg/hour.

- Automated moisture and temperature control systems.

- Multieteapa drying technology to avoid paste breakage.

- CIP Cleaning Systems (Cleaning In Place) To guarantee hygiene.

Machines to elaborate fresh handmade and industrial folder

For specialized companies in fresh pasta, There are production lines designed to conserve texture, Product taste and humidity.

Types of fresh folder machines:

- Vertical or horizontal presses: Ideal for Raviolis, Tortellinis and lasagas.

- Laminating machines: They flatten the dough to obtain uniform leaves.

- Formators and automatic filler: Perfect for stuffed pasta.

- Pasteurizadores: They eliminate pathogens without altering product quality.

- Soft coolers and dryers: They keep the fresh paste with an extended useful life.

This type of machinery is ideal for companies that distribute gourmet supermarkets, Specialized restaurants or stores.

Short and long paste production line: Versatility in formats

Many factories need to produce Short and long paste In the same installation. For this, There are versatile production lines that allow you to quickly change format.

Short dough: penne, fusilli, rigatoni, butterflies, etc.

Wide pasta: spaghetti, fettuccine, linguini, tagliatelle, etc.

These lines are equipped with interchangeable molds and adjustable cutting systems, which allows a rapid transition between types of pasta without interrupting production.

Paste manufacturing extrusion technology

The Pasta extrusion It is the heart of the production line. This process applies pressure to the dough to push it through bronze or teflon molds, shaping pasta.

Advantages of extrusion:

- Uniformity in the size and shape.

- Precise moisture and temperature control.

- Ability to use different types of flour (hard wheat, soft wheat, rice, legumes).

Modern extruders have high energy efficiency engines and digital control panels with touch screen.

Compact Pasta Production Line: Solutions for SMEs

Las Compact Pasta Production Lines They are ideal for small and medium enterprises that wish to professionalize their production without the need for large facilities.

Key benefits:

- They occupy less space.

- They are more affordable.

- Easy to install and maintain.

- Ideal for middle volumes (50–500 kg/hour).

They can work with personalized molds and offer professional results, Perfect for family or artisanal businesses that wish to climb their production.

Filled pasta machine line: ravioli, Tortellinis and more

The production of stuffed paste requires precision and care at each stage, From kneading to product sealing. Machines designed for this purpose include:

- Dosing filler: They control the exact amount of filling.

- High pressure sealers: They assure that the filling does not escape during cooking.

- Rotary molders: They allow unique forms like hearts, Remedy, stars, etc.

This market segment is highly profitable, since consumers value the quality and presentation of this type of gourmet products.

Industrial Pasta Factories: Personalized design and automation

Each factory may need a personalized design according to their commercial objectives, location, available space and variety of products.

Design elements:

- Machinery distribution to optimize workflow.

- Centralized control systems with SCADA panels.

- Stages automation, Adaptable to company growth.

- Integration with ERP systems for complete traceability.

Machinery manufacturers offer technical assistance, personalized installation and training to guarantee the success of each project.

Current trends in the pasta machine industry

The pasta industry is in constant technological evolution. Some of the most relevant trends include:

- Digitization of the process: Remote line control, predictive maintenance and data collection in real time.

- Sustainability: Reduction of energy consumption, Water reuse and recyclable materials.

- Production flexibility: modular lines that easily adapt to new forms, recipes or sizes.

- Food security: Advanced sensors, Total traceability and compliance with international standards such as HACCP and FDA.

Considerations to choose the best machine line for pasta production

When investing in a production line, It is essential to take into account several aspects:

- Desired production capacity.

- Type of pasta that you want to elaborate.

- Space available on the plant.

- Ease of maintenance and cleaning.

- Technical support and available spare parts.

- Health and export regulations.

Having a trust provider is key to ensuring that investment translates into efficiency, Long -term quality and profitability.

Conclusion: Technology at the service of tradition

Pasta is a traditional food that has adapted to modern times. Thanks to pasta production machines, Today you can make high quality pasta quickly and efficiently, Without losing its original flavor.

Both small businesses and large factories can use these production lines to improve their business and satisfy more customers.