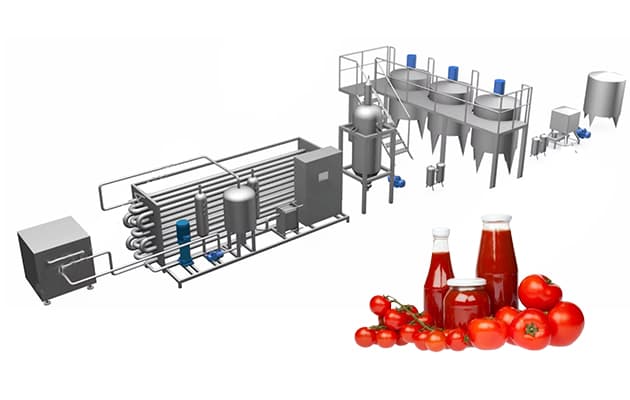

Introduction to the tomato sauce production line

The Tomato sauce production line It is an industrial system designed to transform fresh tomatoes into sauce ready for consumption or packaging. This type of machinery is fundamental in the modern food industry, especially in countries with strong agricultural production or high demand for tomato -based products. The automation of this process not only improves efficiency, but guarantees quality, food security and consistency of the final product.

Importance of automated tomato sauce production

The demand for packaged tomato sauce has grown exponentially due to factors such as:

- Greater consumption of prepared foods

- Changes in urban eating habits

- Expansion of fast food chains and restaurants

- Exports of processed products to international markets

A Automatic tomato sauce production line allows you to satisfy these large -scale demands, reducing labor costs and minimizing human errors.

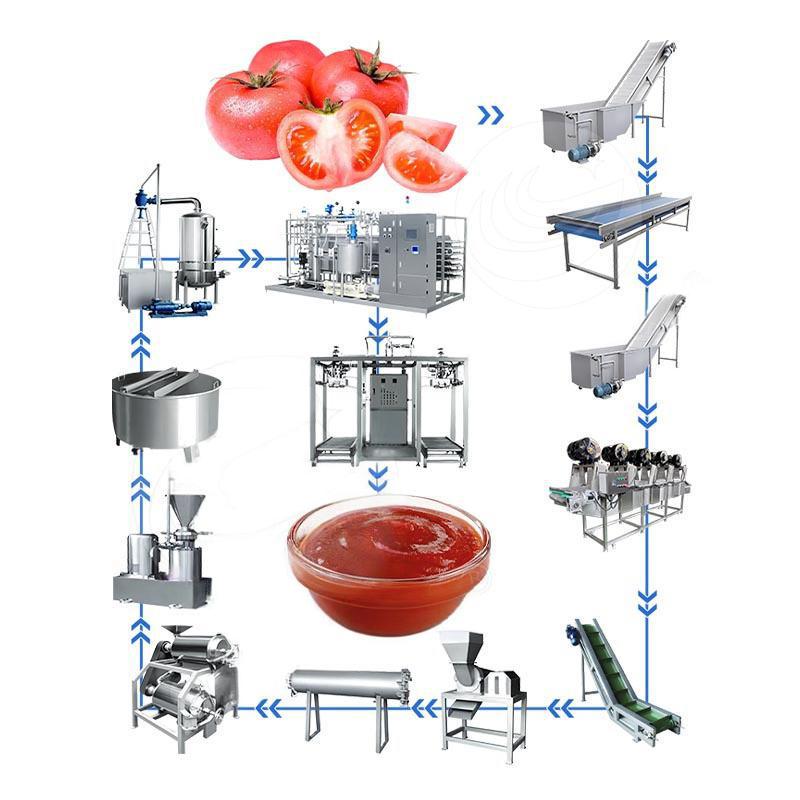

Components of a tomato sauce production line

Next, The main machines that make up a complete line are described:

1. Fresh tomato conveyor

Receive the tomatoes and transfer them to the cleaning areas.

2. Tomato washing machine

Clean dust tomatoes, pesticides and land through water jets or vibrations.

3. Manual or optical inspection

It allows to eliminate damaged tomatoes or foreign bodies.

4. Crusher or disintegrator

Reduce pulp tomatoes, facilitating posterior heat treatment.

5. Preheater

Heat the pulp to temperatures between 65 ° C and 75 ° C to inactivate enzymes and facilitate peeling.

6. Refigress The Prapeador

Separate the skin, unwanted seeds and fibers to obtain fine puree.

7. Intermediate storage tanks

Allow temporary collection before cooking.

8. The evaporator

Concentrate the tomato until the desired consistency (According to the Brix Objective).

9. Ingredient mixer

Sugar are added, sal, vinegar, spices or other ingredients to standardize the recipe.

10. Sterilizer

Eliminates pathogenic microorganisms and prolongs the life of the product.

11. Automatic packaging

Fill the tomato sauce in bottles, jars or sachetts in a hygienic and precise way.

12. Tagger and Packer

Place labels and packed the final product for commercialization.

Technical parameters of the tomato sauce production line

| Machine | Standard model | Ability | Power (kW) | Contact material |

|---|---|---|---|---|

| Tomato washing machine | LW-1000 | 1000 kg/h | 2.2 | Stainless steel 304 |

| Tomato crusher | TD-500 | 500 kg/h | 3.0 | Stainless steel 304 |

| Preheater | PH-600 | 600 L/h | 4.5 | Stainless steel 316 |

| Double stage refining | RF-2ST | 800 kg/h | 5.5 | Stainless steel 316 |

| Vacuum cooker | VC-500 | 500 L | 9.0 | Stainless steel 304 |

| Automatic packaging | AFM-8B | 2000 Packaging/hour | 3.2 | Stainless steel 304 |

| Automatic labeling | LAB-01 | 1800 uds/h | 1.2 | Stainless steel 304 |

| Box packer | PCK-03 | 20 boxes/minute | 2.5 | Stainless steel 304 |

Use: These values can vary according to manufacturer and personalized configuration.

Types of products derived in the production line

A Tomato sauce production line well equipped can be adapted to produce multiple variants of the product:

- Natural sauce without additives

- Salsa with spices (SHE, basil, oregano)

- Ketchup sauce

- Pizza parsley

- Tomato concentrate (tomato paste)

- Tritturated canned tomato

Real applications in industry

Companies that use this type of line include:

- Canned factories

- Sauces and dressing industries

- Food suppliers to large supermarket chains

- Processed food exporters

- Agricultural cooperatives

A concrete example: A company in Peru uses an automatic line of 2 tons per hour to supply markets in Europe and Asia with gourmet sauces.

Advantages of an automated production line

- High production efficiency: until 10 tons per working day

- Reduction of labor: operated by 2–3 technicians

- Product quality stability

- Greater useful life by adequate sterilization

- Compliance with international standards (HACCP, ISO 22000)

Maintenance and cleaning of the tomato sauce line

To guarantee optimal functioning and complying with sanitary standards, It is recommended:

- Daily cleaning: With CIP systems (Clean In Place)

- Weekly Review of Valves and Pipes

- Monthly Lubrication of engines and bearings

- Semiannual calibration of sensors and thermometers

- Preventive substitution of stamps and together each 6 months

Recommendations to choose a good production line

- Evaluate the desired production capacity

- Make sure the materials are Stainless steel Food grade

- Prefer systems with PLC automation and touch screen

- Consider companies with Post -sales and technical support service

- Verify the Compatibility with own recipes

Frequently asked questions (Rfq)

What is the price of a tomato sauce production line?

It depends on the capacity (from 500 kg/h to 5 ton/h). A basic line can begin in $25,000 USD, while complete automated can overcome $150,000 USD.

Can it be used for other products in addition to tomatoes?

Yeah. Some lines are versatile and allow similar fruits to process (mango, guava, peppers, etc.).

What certifications should the machines have?

- CE certificate (For Europe)

- FDA (for the US)

- ISO 9001 / ISO 22000

- HACCP

How long does the installation and start -up lasts?

Between 10 y 30 days, According to plant size.

Does specialized technicians require?

The supplier generally offers training. Once trained, An operator can manage the entire line with minimal supervision.

Recommended manufacturers

An outstanding company is DT Food Machine Co., Ltd., manufacturer specialized in food processing solutions, With more than 20 years of experience exporting more than 50 countries. Offers modular lines of custom tomato sauce, installation services, guarantee and spare parts.

Conclusion

The Tomato sauce production line It is a key investment for any company that wishes to enter the processed food market or expand its capacity. Its automation guarantees efficiency, Safety and scalability. Adapting to different types of sauce and production volumes, These lines offer comprehensive solutions to satisfy both the local and the international market.