Introduction

Yogurt is one of the most consumed dairy products in the world thanks to its flavor., nutritional value and versatility. With the growth of the healthy food market, more and more companies, farms and factories invest in a complete yogurt production line.

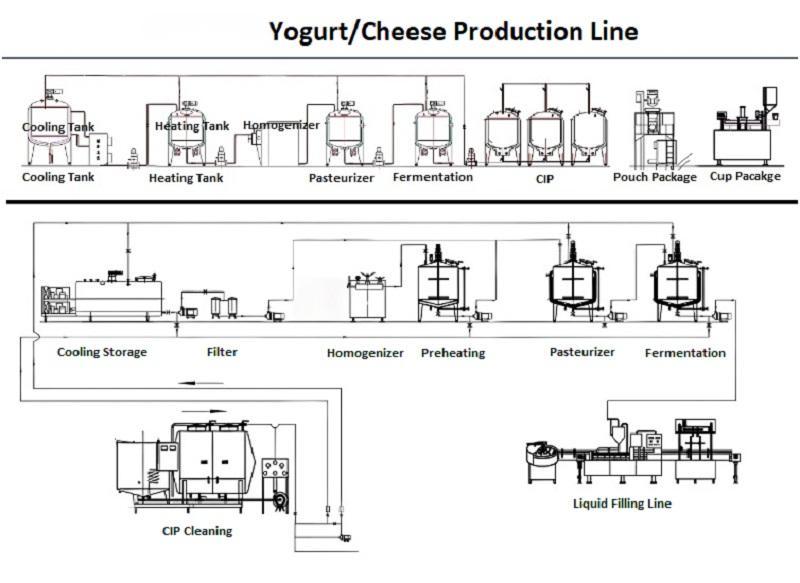

But, What equipment does a professional yogurt making line actually include??

A complete line is not only composed of a yogurt machine, but of a set of coordinated systems: from receipt of milk to final packaging.

In this we will explain all essential components, its function, and how they connect together to form an efficient industrial line, hygienic and profitable.

🧭 1. Main stages of yogurt production

Before talking about the equipment, It is important to understand the basic stages of the yogurt production process:

- Reception and filtering of milk

- Standardization of fat content

- Pasteurization and homogenization

- Cooling and sowing of the dairy crop

- Controlled fermentation

- Final cooling of the yogurt

- Fill, sealing and packaging

- Refrigeration and storage

Each of these stages requires specific machines that guarantee quality, food safety and stability of the final product.

⚙️ 2. Main components of a complete yogurt production line

Next, we will see What does an industrial yogurt production line include? and what is the role of each machine.

🥛 2.1 Milk reception and filtering system

Function:

It is the first stage of the process. Here raw milk is received from farms or tank tanks., and filtered to remove impurities or solid residues.

Main equipment:

- Stainless steel milk filter

- Receiving tank with volume measurement

- Sanitary breast pump

Technical Characteristics:

- Made of SUS304 stainless steel

- Ability: 500L – 10,000L

- Equipped with sanitary valves and airtight lids

👉 This system ensures that the raw material is clean and meets quality standards for further processing.

🧴 2.2 Standardization and mixing tank

Function:

At this stage the fat and solids content of the milk is adjusted.. Powdered milk can be added, cream or stabilizers to obtain the desired texture.

Equipment included:

- Mixing tank with agitator

- Temperature control system

- Flow meter and scale

Technical details:

- Ability: 300L – 5,000L

- Low speed reducer motor

- Variable speed control

- Propeller or anchor type agitator

This tank is also used for dissolve ingredients like sugar, fruits or flavors before pasteurization.

🔥 2.3 Milk pasteurizer

Function:

He pasteurizer It is a key machine in the yogurt production line. Its purpose is to eliminate pathogenic bacteria without altering the flavor or nutritional properties of the milk..

Types of pasteurizers:

- Tank type pasteurizer (batch)

- Plate pasteurizer (Htst)

Working temperature:

- 85°C to 95°C for 15–30 minutes (for traditional yogurt)

- Subsequent cooling to 42°C for culture inoculation

Characteristics:

- Fully enclosed structure

- Automatic temperature control

- CIP SYSTEM (on-site cleaning)

👉 One industrial yogurt making machine always includes a high quality pasteurizer, because pasteurization determines the shelf life of the product.

⚙️ 2.4 High pressure homogenizer

Function:

The homogenizer reduces the size of fat particles in milk, improving texture, the taste and stability of yogurt.

Specs:

- Working pressure: 20–25 MPa

- Ability: 100L/h – 5,000L/h

- Stainless steel manufacturing

Benefits:

- Prevents cream separation

- Gives a smoother and creamier texture

- Improves digestibility

This step ensures that the yogurt has a uniform consistency and be visually attractive.

❄️ 2.5 Cooling and inoculation system

After pasteurization and homogenization, The milk must be cooled quickly until 42–45°C, ideal temperature for fermentation.

Teams:

- heat exchanger

- Rapid cooling tank

- Digital temperature control system

Then add the lactic acid bacteria starter culture (Lactobacillus bulgaricus y Streptococcus thermophilus).

Characteristics:

- Precise temperature control

- Sealed system to avoid contamination

- Slow agitation for uniform crop distribution

🧫 2.6 Yogurt fermentation tank

Function:

He Yogurt fermentation tank It is the heart of the process. Here the transformation of milk into yogurt occurs through controlled fermentation.

Standard conditions:

- Temperature: 42°C

- Duration: 6 a 8 hours

- pH final: 4.4 – 4.6

Tank Features:

- Fully thermally insulated

- Automatic time and temperature control

- Optional stirring system

- Sanitary valves and pressure caps

👉 Some models have automatic data logging, allowing precise and constant control of the process.

🧊 2.7 Final cooling system

Once fermentation is complete, Yogurt must quickly cool 4–8°C to stop bacterial activity and preserve its texture.

Equipment included:

- Plate cooler

- Refrigerated storage tank

- refrigeration compressor

This system maintains product freshness before filling or storage.

🧃 2.8 Yogurt filling machine and sealant

Function:

Filling is a critical stage to maintain hygiene and commercial presentation of the product.

Types of filling machines:

- Automatic glass or cup filler

- Bag or pouch filler

- Plastic bottle filler (for liquid yogurt)

Characteristics:

- Volume control by dosing pump

- Heat sealed or with aluminum lid

- Hygienic filling system in sterile environment

👉 Las yogurt filling machines Modern features include UV sterilization and integrated CIP cleaning systems.

📦 2.9 Packaging and labeling system

A complete line may also include additional machines for final presentation:

Additional equipment:

- Automatic labeling

- Tray or box packing machine

- Conveyor belt

- Automatic palletizer

These systems improve logistics efficiency and the appearance of the product in the market..

🧪 3. Optional equipment depending on the type of yogurt

Depending on the type of yogurt that is produced (natural, Greek, liquid, With fruits), other modules can be included:

| Type of Yogurt | Recommended Additional Equipment |

|---|---|

| Greek yogurt | Whey separation system, filter or centrifuge |

| Yogurt with fruits | fruit mixer, flavor dispenser |

| liquid yogurt | Storage tank with continuous agitation |

| Pasteurized drinking yogurt | Final pasteurization unit and aseptic filler |

💡 4. General technical characteristics of the complete line

| Parameter | Valor / Typical range |

|---|---|

| Production capacity | 500L – 10,000L per batch |

| Material principal | Stainless steel its 304/316 |

| Control | PLC + touch screen |

| Energy source | Electric / vapor / refrigeration |

| Pasteurization temperature | 85–95°C |

| Fermentation temperature | 42°C |

| Storage temperature | 4–8°C |

| CIP cleaning efficiency | ≥ 99% |

🏭 5. Advantages of an automatic yogurt production line

- High production efficiency: can operate 24 hours without interruption.

- Precise quality control: Temperature, automatic time and pH.

- Compliance with international health standards (CE / ISO / HACCP).

- Labor cost reduction: Fewer operators required.

- Versatility: Allows different types of yogurt to be produced with the same line.

- Ease of cleaning and maintenance thanks to the CIP system.

💰 6. Investment and estimated price

He price of a complete yogurt production line depends on capacity and level of automation.

| Ability (L/h) | Configuration | Approximate price (USD) |

|---|---|---|

| 200 – 500 L/h | semi-automatic line | 15,000 – 25,000 |

| 1,000 – 2,000 L/h | Medium automatic line | 30,000 – 60,000 |

| 3,000 – 5,000 L/h | Complete industrial line | 70,000 – 120,000 |

| More than 10,000 L/h | Custom line | 150,000+ |

👉 Although the initial investment is high, The return is achieved quickly due to labor savings and increased productivity..

🌍 7. Applications of a yogurt production line

- Dairy factories

- Agricultural processing plants

- milk cooperatives

- Healthy food brands

- Fermented beverage projects

It is also used to produce kefir, fermented milk, probiotic yogurt and other dairy derivatives.

🔧 8. System maintenance and cleaning (CIP)

The Automatic cleaning (CIP) It is a fundamental system to maintain hygiene in a yogurt plant.

Typical CIP cycle:

- Rinse with warm water

- Washing with alkaline solution (60–70°C)

- Intermediate rinse

- acid wash (if required)

- Final rinse with purified water

The CIP system reduces the risk of contamination and extends the useful life of the equipment.

🚀 9. How to choose a suitable yogurt production line

- Determine daily production capacity.

- Select a manufacturer with experience in dairy equipment.

- Verify the quality of stainless steel and health certificates.

- Choose an easy-to-use PLC control system.

- Confirm the availability of spare parts and after-sales service.

🏁 complete yogurt production line

A complete yogurt production line includes much more than just a machine. It is an automated system that integrates reception, pasteurization, fermentation, cooling and packaging, guaranteeing a final product of high quality and long useful life.

Invest in one industrial yogurt making machine or one Complete line means improving efficiency, ensure hygiene and increase competitiveness in the healthy food market.