Introduction

In the world of baking and the dessert industry, los ice cream cone making machine They have become an essential product. Not only are they the perfect companion for artisanal or industrial ice cream., but they also represent a very profitable business opportunity for bakeries., ice cream parlors and food factories.

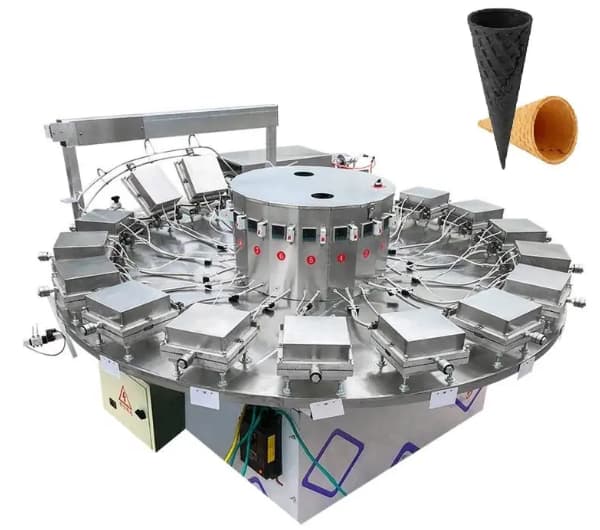

The ice cream cone making machine It is the key tool to produce these crispy wafers quickly, uniform and large scale.

We will thoroughly explore everything related to these machines: How they work, What types exist, its technical specifications, competitive advantages, frequently asked questions (Rfq) and purchase recommendations.

What is an ice cream cone making machine?

The ice cream cone making machine is a specialized equipment designed to manufacture wafer cones of different shapes, sizes and thicknesses. It works using hot molds that press the dough and then automatically roll it into a cone shape..

This process guarantees:

- Uniform production.

- High speed.

- Crispy, golden cones.

- Ability to customize sizes and designs.

Types of ice cream cone making machines

1. Manual machines

- Ideal for small artisanal ice cream shops.

- Low initial cost.

- They require more time and labor.

- Limited production (50-200 Cones per hour).

2. Semi-automatic machines

- They mix automation with manual control.

- Average capacity: 200-800 Cones per hour.

- Suitable for medium-sized businesses.

3. Industrial automatic machines

- Completely automated.

- Ability to 1000 more than 5000 Cones per hour.

- PLC control, adjustable temperature and automatic winding.

- Ideal for factories and wholesale distributors.

Advantages of using an ice cream cone machine

- Production efficiency – produces hundreds or thousands of cones in a few hours.

- Uniform quality – all wafers have the same thickness and shape.

- Versatility – allows small cones to be manufactured, medium, large and even special cones for soft ice cream.

- Cost savings – reduces the use of labor.

- Greater hygiene – stainless steel design, easy cleaning.

Technical parameters of an ice cream cone making machine

Below is a table with typical specifications:

| Model | Ability (Cones/hour) | Power | Machine material | cone size | Approximate weight |

|---|---|---|---|---|---|

| DT-CN20 | 500 – 1000 | 6 kW | Stainless steel + cast iron molds | 4–7 cm diameter | 250 kg |

| DT-CN40 | 2000 – 3000 | 12 kW | Stainless steel | 6–10 cm diameter | 450 kg |

| DT-CN60 | 4000 – 6000 | 18 kW | Stainless steel | Customizable | 750 kg |

| DT-CN80 | 8000+ | 25 kW | Stainless steel Food grade | Different shapes | 1000 kg |

Applications of ice cream cone machine

- Artisanal ice cream shops: produce fresh cones on the premises.

- Industrial factories: mass production for distribution.

- Bakeries and cafes: add wafers as a complement to desserts.

- Supermarkets and food chains: produce packaged cones.

Factors to consider before purchasing a machine

- Production capacity – choose according to your demand.

- Cone size – make sure the machine can adjust to different measurements.

- Energy consumption – important in industrial production.

- Manufacturing materials – stainless steel for greater hygiene.

- Automation level – manual, semi-automatic or automatic.

- Technical support and spare parts – essential for continuous use.

Frequently asked questions (Rfq) about ice cream cone machines

1. What is the price of an ice cream cone making machine??

Cost depends on level of automation and capacity. A small machine can cost between 2,000 y 5,000 USD, while an automatic industrial line exceeds the 30,000 USD.

2. Can the cone size be customized?

Yeah, The molds are interchangeable and allow cones of different diameters and lengths to be manufactured.

3. How long does it take to make a batch of cones??

An automatic machine can produce 2000 a 5000 Cones per hour, Depending on the model.

4. What is the useful life of these machines?

With adequate maintenance, They can last between 8 y 12 years.

5. Is it difficult to operate?

No. Modern versions come with digital control (PLC) and easy-to-use touch screens.

MAINTENANCE TIPS

- Clean the molds after each day.

- Check the electrical and heating system every month.

- Use only food oils for lubrication.

- Store in a dry and ventilated space.

Ice Cream Cone Market Trends

Ice cream consumption around the world continues to increase, especially in emerging markets in Latin America and Asia. This opens up great opportunities for companies that invest in ice cream cone making machines high capacity.

Besides, There is a growing demand for wafers with innovative flavors: chocolate, matcha, strawberry, activated carbon, etc. Modern machines can now produce cones with different recipes and colors.

Ice cream cones

The ice cream cone making machine It is a strategic investment for any business related to ice cream and pastries.. From small entrepreneurs to large factories, This equipment guarantees efficiency, quality and growth.

In DT Food Machine, We are specialized manufacturers of automatic and semi-automatic ice cream cone lines.. We offer custom models, technical support and competitive pricing to help our customers expand their business.

If you are looking for a reliable solution to produce ice cream cones profitably, We are your best partner in the industry!!