Introduction to the liquid filling machine

The liquid filling machine It is an essential team in food industries, beverages, cosmetics, Pharmaceutical and chemicals. Thanks to its ability to automate the bottles filling process, vials, Bags or other packaging, These machines increase efficiency, reduce errors and improve hygiene in production lines.

In this detailed article, We will explore everything related to Liquid filling machines: from common types and uses to technical specifications, customization options and examples of quotation requests (Rfq).

Types of liquid filling machine according to the type of product

Food Liquid Filling Machine

Designed to fill juices, agua, leche, edible oil and other edible drinks or liquids.

Main features:

- Contact with stainless steel grade degree (Its304 or its316)

- Optional with CIP cleaning system (Cleaning in Place)

- Suitable for cold or hot products

Liquid chemical filling machine

Suitable for corrosive liquids as disinfectants, Diluted detergents or acids.

Characteristics:

- Anticorrosive materials (PVC, PP, PTFE)

- Fill without contact for hazardous substances

- Splashes protection

Cosmetics filling machine and personal care products

Ideal for liquid creams, Gels, shampoos, perfumes and more.

Characteristics:

- Precise dosing system (Peristaltic bombs, pistons)

- Variable viscosity control

- Special design containers filling options

Classification according to the automation level

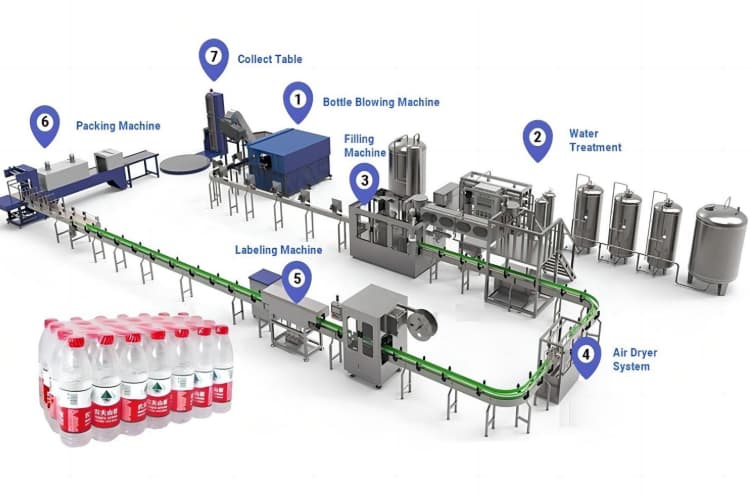

Automatic liquid filling machine

They integrate filling functions, covered, Automatic labeling and control.

Advantages:

- High production speed (until 24,000 Packaging/hour)

- PLC control with touch screen

- Minimum human intervention

Semi -automatic fluid filing machine

Operated with manual assistance. It requires loading the containers and activating the filling by pedal or button.

Advantages:

- Low investment cost

- Easy to use and maintain

- Ideal for small and medium enterprises

Manual filling machine

Ideal for laboratories, Samples, or artisanal production.

Advantages:

- Portable and economic

- Manually controlled precision

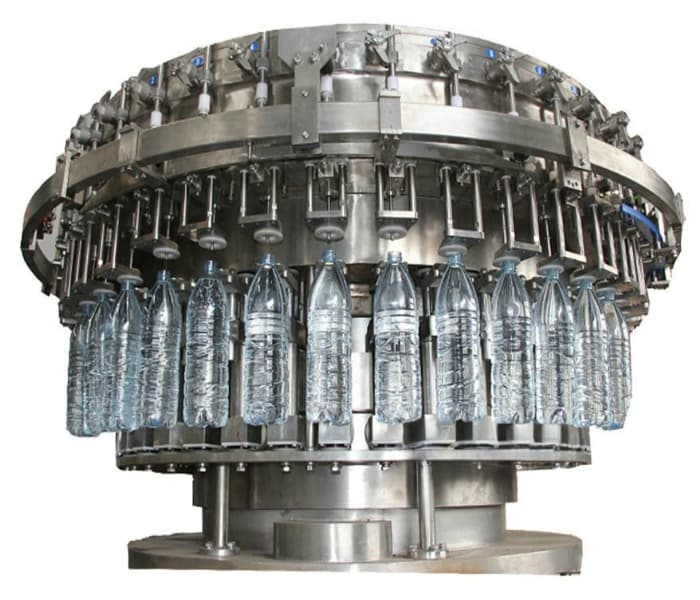

Liquid bottles filling machine

General technical characteristics

| Specification | Detail |

|---|---|

| Model | Shove / CGF18-18-6 / CGF32-32-10 |

| Production capacity | 300 a 24,000 bottles/hour |

| Bottle types | PET, glass, HDPE, Special bottles |

| Filling volume | 50 ml a 5 L |

| Filling precision | ±1% |

| Control system | PLC Siemens or Mitsubishi with HMI screen |

| Electrical requirement | 220V/380V, 50/60Hz |

| Air pressure | 0.6–0.8 MPa |

| Contact material | Stainless steel its 304/their316 |

| Dimensions | Variable according to model |

| Weight | 300–7000 kg |

Liquid filling machine per type of container

Plastic bottles filling machine (PET/HDPE)

- Common in water plants, juices, chemical products

- Automatic adjustment for different packaging sizes

Glass bottles filling machine

- Ideal for liqueurs, perfumes, Premium juices

- Compatible with vacuum systems to avoid spills

Bag filling machine and envelopes (doypack/sachet)

- Very used in sauces, gel antibacterial, Honey, etc.

- Thermal sealing and coding options by date

GARRAFON FILLING MACHINE (5 liters, 20 liters)

- Full pickled cycles, washing, Filling and covered

- Production of up to 1200 Carphones/Hour

Filling methods in liquid machines

| Filling method | Typical application |

| Filling by gravity | Agua, juices without gas |

| Vacuum filled | Liqueur, perfumes |

| Piston filled | Sauces, creams, viscous products |

| Filled by overflow | Transparent bottles drinks |

| Peristaltic pump filled | Pharmaceutical liquids, precision cosmetics |

Key parameters to consider before buying

- Time production capacity

- Compatibility with different volumes and packaging forms

- Required filling precision

- Liquid viscosity level

- Type of cover necessary

- Budget available

Common industry applications

| Industry | Examples of products |

| Food | Agua, juices, leche, oil, Honey, sauces |

| Cosmetic | Shampoo, gel, liquid cream, tonic |

| Pharmaceutical | Syrups, Injectable solutions, disinfectants |

| Chemical | Acid, cleaner, detergent, fertilizers |

| Alcoholic beverages | Vino, liqueur, ron, vodka |

Frequently asked RFQ questions for liquid machine

- What is the production capacity per hour?

- It varies between 300 y 24,000 units per hour according to the model.

- What types of bottles or containers admit?

- PET, glass, HDPE, doypack, sachet, carboys, among others.

- Can I fill hot or viscous fluids?

- Yeah, with a piston filling or optional heater.

- Does it include cover or labeling system?

- Automatic models can integrate covered and labeling.

- What type of energy requires?

- Electric 220V/380V + compressed air (0.6 MPa).

- Can you adapt to different volumes?

- Yeah, by adjusting or change of nozzles.

- What certifications does the machine have?

- CE, ISO9001, SGS. Specific models can meet GMP.

- Can you customize the machine with my brand or logo?

- Yeah, We offer OEM and ODM.

- What is the average delivery time?

- Of 15 a 45 days depending on the model and customization.

- Is post -sales technical support offered?

- Yeah, Online and optionally on site.

Estimated price range (Reference 2025)

| Machine type | Estimated price (USD) |

| Manual machine the laptop | $500 – $1,500 |

| Semi -automatic machine | $1,500 – $5,000 |

| Small automatic machine (1,000–3,000 BPH) | $6,000 – $15,000 |

| High speed automatic line | $25,000 – $100,000+ |

Main Global Manufacturers and Suppliers

- KRONES AG (Germany)

- Sidel Group (France)

- Newamstar (China)

- Zhangjiagang King Machine (China)

- Filpack (India)

- Prominent Fluid Controls (Mexico)

Current trends in fluid -filled machines

- Remote control by IoT and SCADA Systems

- Fill without contact for sterile products

- Change of format without tools (tool-less)

- Quality monitoring with smart cameras

- Energetically efficient systems

Conclusion

The liquid filling machine It is an indispensable tool for any company that processs and markets liquid products. Choosing the appropriate model implies considering multiple factors such as the type of liquid, Production level, Budget and regulatory requirements.

Either for a local venture or an industrial plant, There are flexible and scalable solutions in the global market. Remember to always request technical catalogs, test videos and consult all your doubts on the RFQ before closing your purchase.