The export of Wafer making machine to Mexico has become a growing trend due to the rapid development of the ice cream sector, pastries and snacks in the country. In cities like Mexico City, Monterrey, Guadalajara, Puebla and León, the demand for cones, wafers and waffle products continue to increase thanks to the growth of artisanal ice cream parlors, franchise chains and industrial factories. For this reason, Both small and medium-sized companies are looking for industrial wafer making machines, improving efficiency, product quality and consistency.

1. Growth in wafer consumption in Mexico

Mexico is one of the most dynamic markets in Latin America in consumption of ice cream and derived products.. The factors driving this demand are:

- Increase in artisanal ice cream parlors.

- Expansion of international soft ice cream and gelato franchises.

- Greater consumer preference for gourmet or personalized desserts.

- Cold drinks and ice creams as popular products throughout the year.

Due to this growth, companies look for automatic barquillo machines that guarantee uniform production, high capacity and hygiene standards to meet the demands of the Mexican market.

2. Why Mexico imports wafer machinery

Although Mexico has a developed food industry, the technology of industrial wafer making machines It is usually imported because:

2.1 High need for automation

Mexican manufacturers require equipment with:

- Temperature Digital Control

- Automatic dough feeding

- Continuous production

- Uniform color and texture

- Regulatory compliance in stainless steel

Exported automatic machines offer advanced technology and energy efficiency.

2.2 More competitive prices

Machines imported from Asia or Europe usually have a better cost-benefit ratio than local production.

2.3 Complete customization

When exporting a wafer making machine to Mexico, the client can request:

- Wafer size

- Cones, rolls or cups

- Thickness and texture

- Custom molds

- Logo or special design engraved

2.4 Technical support and spare parts

Reliable providers include:

- Remote training

- Manuals in Spanish

- Long life spare parts

- After-sales assistance

This facilitates continuous operation in Mexican factories.

3. Machine to make wafers to Mexico for the Mexican market

Mexican buyers use many related terms when searching for this machinery, For example:

- Wafer making machine to Mexico

- Automatic ice cream cone machine for Mexico

- Industrial equipment for making wafers

- Wafer production line sent to Mexico

- Wafer cone making machine Mexico

- Rotary oven for industrial wafers

- Sugar cone making machine Mexico

4. Types of machines to make wafers most requested in Mexico

4.1 Semi-automatic barquillo machines

Suitable for:

- Artisanal ice cream shops

- Restaurants

- Small factories

Characteristics:

- 12–24 plates

- Ability: 1,000–2,000 pieces per hour

- Easy operation and maintenance

- Excellent cost-benefit ratio

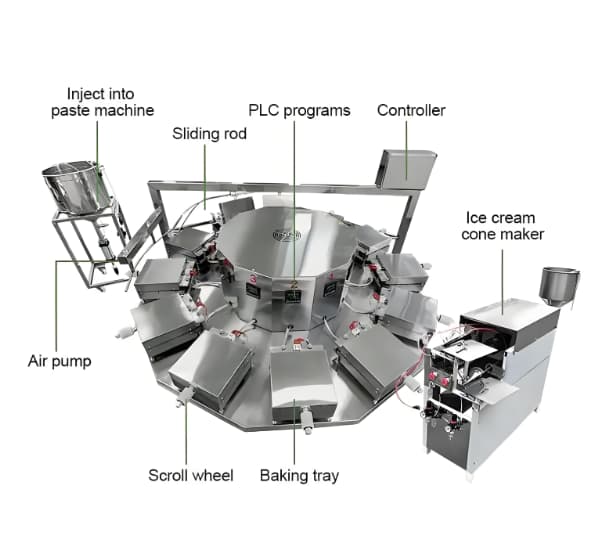

4.2 Industrial automatic machines

Most popular among medium and large factories. include:

- 36–120 baking plates

- Production: 5,000–12,000 wafers per hour

- Automatic dough feeding

- PLC system

- Continuous rotary baking

- Automated winding and forming

This version guarantees high efficiency and homogeneous results.

4.3 Complete wafer production lines

For large Mexican food companies. The line integrates:

- Automatic dough mixer

- Industrial rotary kiln

- Automatic winding system

- Cooling band

- Wafer counter and stacker

- Final packaging

This complete solution maximizes productivity and reduces labor.

5. Important technical specifications for Mexican customers

5.1 Materials and structure

- Stainless steel Food grade

- Heat resistant cast iron plates

- Certified non-stick surface

5.2 Smart control

- PLC with touch screen

- Temperature and time setting

- Color and cooking control

- Alarm and security system

5.3 Power options

Mexico mainly uses:

- Gas LP

- Gas natural

- Electricity

Gas machines are usually preferred for their lower operating cost.

5.4 Wafer customization

Exporting manufacturers offer:

- Standard cones (70–120 mm)

- Long roll wafers

- Copas o bowls wafer

- Jumbo cones

5.5 Production capacity

Common options for Mexico:

- Low capacity: 1,000–2,000 pieces/hour

- Media: 3,000–7,000 pieces/hour

- Alta: 10,000–15,000 pieces/hour

6. Shipping of wafer machinery to Mexico

Export a Wafer making machine to Mexico requires proper logistics. Machines are normally shipped by sea to:

- Port of Manzanillo

- Port of Veracruz

- Port of Lázaro Cárdenas

6.1 Packaging

- Treated wooden boxes

- Internal metal reinforcements

- Anti-humidity and anti-vibration protection

6.2 Customs documentation

Includes:

- commercial invoice

- Packaging list

- Certificate of origin

- Code hss (For example 841981 or similar)

6.3 Delivery times

- Manufacturing: 15–35 days

- Maritime transport: 20–35 days

7. Opportunities in the Mexican market

Export a wafer making machine to Mexico represents clear advantages:

7.1 High growth of the ice cream sector

Mexico has an active market throughout the year.

7.2 Lack of specialized local manufacturers

Highly automated machines continue to be mostly imported.

7.3 Product Diversity

The Mexican market demands:

- Traditional wafers

- sugar cones

- gourmet cones

- Flavored wafers

7.4 Greater investment in automation

Factories seek to reduce costs and improve efficiency.

8. How to choose the best machine for the Mexican market

- Define the required production level.

- Ensure availability of technical support in Spanish.

- Check the type of gas or energy used in the factory.

- Request product testing before shipping.

- Choose customized molds according to the target market.

- Evaluate warranties and spare parts included.

Machine to make wafers to Mexico for the Mexican market

The export of Wafer making machine to Mexico offers a highly favorable outlook for food machinery manufacturers and distributors. The combination of growing demand, little local competition, variety of applications and need for automation makes the Mexican market a strategic destination. From artisanal ice cream parlors to large corporations, all require automatic cone machines, industrial equipment for making wafers y complete production lines that guarantee quality, volume and efficiency.