In the competitive world of the production and marketing of ice cream, The presentation and quality of edible cones play a fundamental role. The ice cream cones It has become an essential tool for ice cream shops, Food Factories, Gastronomic entrepreneurs and industrial suppliers. This detailed guide offers you a complete vision of the types of machines, Its functions, benefits, And how to choose the right option for your business.

Types of ice cream cones

The industry offers various alternatives depending on the production level, The budget and the desired cone type. Next, We explore the main types of ice cream cones available in the market.

Automatic machine to make waffle cones

Automatic machines are ideal for large -scale productions. These units integrate all stages of the process: From the dumping of the dough, cooking, molded to the automatic stack of the cones.

Main advantages:

- High production capacity (until 5000 Cones per hour).

- Continuous operation with low human intervention requirement.

- Uniform quality in each unit produced.

Semi -automatic machine for edible cones

While they are not as fast as automatic, Semi -automatic machines represent an excellent option for small and medium enterprises that seek to maintain more manual control without giving up efficiency.

Outstanding features:

- Digital temperature and time control.

- Interchangeable molds for cones of different sizes.

- Ideal for handmade ice cream shops.

Manual machine to make ice cream cucuruchos

Business that bet on an artisanal or low volume approach can opt for a Manual machine for ice cream cones. This team allows you to elaborate personalized cones, fresh and unique in flavor and texture.

Typical applications:

- Food trucks

- Gastronomic events

- Fairs and festivals

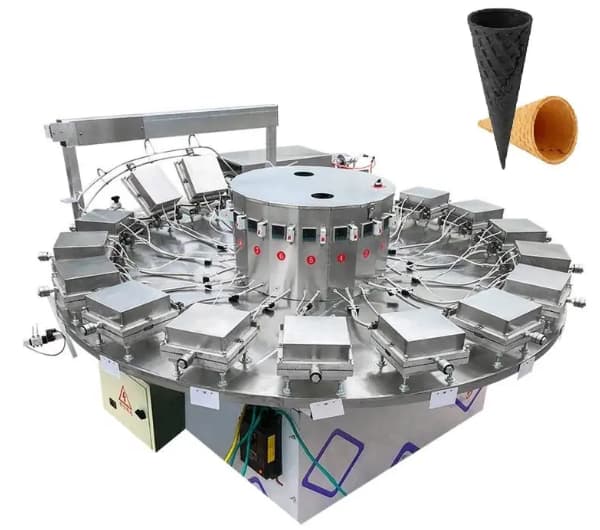

Ice Cream Cones Industrial Machine

The Ice Cream Cones Industrial Machine It is designed to operate in large -scale production lines. These systems are fundamental in ice cream factories or cones suppliers to supermarket and restaurant chains.

Main components

- Automatic mass mixer

- Dosing with flow control

- ROTATORY BUY OF MULTIPLE PLATES

- Rolled system with pneumatic precision

- Cooling conveyor belt

- Automatic classifier and packer

Industrial benefits

- Cost reduction per unit.

- Energy consumption optimization.

- Greater quality control.

Machine to make ice cream boats with flat base

Not all cones have a pointed shape. Some manufacturers prefer flat -based cones, since they can easily support and allow more stable presentations. The Machine to make flat base boats It is equipped with special molds and pressure control during molding.

Varieties of available molds

- Square base

- Round base

- Belgian wide cones

Commercial application

- Soft Serve ice cream cones

- Gourmet desserts

- Cones stuffed with chocolates or sauces

Artisanal ice cream cucuruchos

The trend of consumption towards the artisanal and the local has promoted the use of the Artisanal ice cream cucuruchos, especially in boutique ice cream shops.

Advantages of the artisanal approach:

- Fresh and local ingredients.

- Customization of flavors and colors.

- Greater value perceived by the client.

Technical considerations

- Longer cooking time (90–120 seconds).

- Thicker mass.

- Manual rolled control.

How a machine for ice cream cones works

Although there are different models, the principle of operation of a ice cream cones It usually follows the following stages:

- MIX PREPARATION: The dough usually includes flour, sugar, agua, Egg and vanilla essence.

- Automatic or manual discharge: The dough is poured over hot molds.

- Cooking: the molds close and the dough is cooked for a certain time.

- Rolled and molded: After cooking, The hot dough is rolled in a conical mold.

- Cooling: The cones are allowed to cool to retain their form.

- Stacking and packaging: In automatic machines, This phase is also integrated.

Machine to make sweet cones with chocolate or filling

The cones with filling at the base (generally chocolate or cream) They have gained popularity in recent years. The chocolate stuffed cones Includes an additional nozzle that injects the filling before the final cooling.

Technical requirements

- Filling Pump with Temperature Control.

- Automatic dosing nozzle.

- Internal Sealing System.

How to choose the best machine for ice cream cones

Select the ice cream cones appropriate requires analyzing various key factors:

Production level

- Little (until 300 Cones/day): Manual Machine The Semiautomatic.

- Medium (until 3000 Cones/day): Semiautomatic Machine The Basic Automatic.

- Grande (more than 10,000 Cones/day): industrial production line.

Cone type

- Classic boat

- Cookie cones

- Colored or thematic cones

Budget

The cost can vary from 500 USD (manuals) even more than 80,000 USD (Complete industrial lines).

Advantages of producing your own cones with a professional machine

Invest in one ice cream cones allows business:

- Control the quality of your products.

- Reduce external suppliers dependence.

- Customize your cones according to the brand.

- Increase profit margin.

- Innovate with flavors, exclusive forms and presentations.

TIPS FOR MAINTENANCE AND CLEANING

The correct maintenance of your ice cream cones guarantees a prolonged useful life and food security.

Good practices:

- Clean with wet cloths and neutral products.

- Avoid the use of abrasive sponges.

- Check cables, Periodically electrical sensors and resistances.

- Lubricate weekly mobile axes.

Global trends in cones design

The current market is constantly evolving. Some of the main trends include:

- Vegan or gluten cones

- Cones infused with superfoods

- Activated carbon cones or spirulina (Natural colors)

- Cones with innovative forms (heart, flor, spiral)

Success cases with machines to make ice cream cones

Case 1: Artisanal ice cream shop in Mexico

A small company in Oaxaca acquired a Semi -automatic machine for ice cream cones and tripled its sales in three months by offering fresh and crispy cones with cinnamon flavor.

Case 2: Industrial factory in Argentina

A factory with the capacity to produce 40,000 daily cones implemented a Automatic boat cones line, reducing costs in a 22% annual.

Conclusion: The ice cream cones machine as an innovation tool

Beyond being a simple kitchen team, the ice cream cones represents a competitive advantage for any company related to the ice cream world. Allows to offer a fresh product, custom and high quality, that improves customer experience and business profitability.