1. Introduction to the world of ice cream cone making machine

In the modern ice cream industry, cones or wafers are an essential element that provides texture, flavor and presentation of the final product. Behind every perfectly crunchy cone is a ice cream cone making machine, also known as ice cream wafer making machine o cone making machine.

These machines have revolutionized the way manufacturers produce high volumes of cones., guaranteeing uniformity, quality and efficiency. Whether for a small artisanal ice cream shop or an industrial production plant, cone making machines adapt to different needs, capabilities and budgets.

2. What is an ice cream cone maker??

A ice cream cones is specialized equipment designed to prepare, baking and shaping thin dough cones made primarily of flour, sugar, oil and water.

The process begins with the preparation of the dough, which is then poured into heated metal molds. The machine bakes the dough and, through a rolling or molding system, creates the characteristic cone that is then cooled and packaged.

Depending on the type of machine, production can be completely automatic, semi-automatic or manual. In the case of the automatic ice cream wafer making machines, The entire process – from pouring to ejection of the finished cone – is carried out without human intervention.

3. Types of ice cream cone making machines

3.1 Manual wafer making machine

This type of machine is ideal for small ice cream parlors or artisan businesses.. It consists of a double plate where the dough is placed and rolled manually after baking. Although its capacity is limited, offers complete control over size, cone flavor and texture.

3.2 Semi-automatic cone making machine

Las semi-automatic ice cream cone making machines combine ease of use with faster production. Requires operator to pour batter and remove cones, but the baking and rolling process is assisted by the mechanical system.

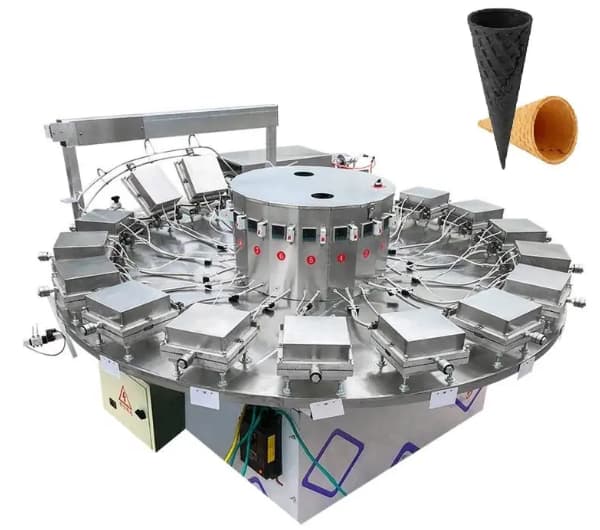

3.3 Automatic ice cream cones

The automatic ice cream wafer machine It is the ideal option for factories or large production plants. It has multiple molds and PLC control, allowing thousands of units per hour to be produced with consistent precision.

These machines are designed for continuous operation, ensuring consistent quality and reducing labor costs.

4. Main components of a cone making machine

A industrial ice cream cone making machine It is made up of several interconnected systems that ensure efficient operation:

| Component | Main Function |

|---|---|

| Mass mixer | Prepare and mix the ingredients until you obtain a homogeneous texture. |

| Dosing system | Control the exact amount of dough poured into each mold. |

| Heating plates | They bake the dough at a constant temperature to obtain crispy cones. |

| Rolling or molding system | Shape the wafer into a cone while it is still hot.. |

| Cooling system | Reduces cone temperature to avoid deformation. |

| control Panel (PLC) | Allows you to adjust parameters such as time, temperature and speed. |

These elements work together to produce high quality cones, ready for packaging or immediate use in ice cream parlors.

5. Ice cream cone production process

The operation of a ice cream cone making machine can be summarized in the following stages:

5.1 Mass preparation

The mixture includes wheat flour, sugar, vegetable oil, water and optional flavorings such as vanilla or cocoa. Industrial mixer guarantees uniform dough.

5.2 Dosing and baking

The dough is automatically distributed into the hot molds. baking plates, made of stainless steel, reach temperatures between 150 °C y 200 °C.

5.3 Rolled or molded

While the dough is still warm and flexible, a roller or mold transforms it into a cone shape. In automatic machines, This process is done without manual intervention.

5.4 Cooling and output

Freshly baked cones are cooled to room temperature using a cooling fan or conveyor belt.

5.5 Packing

Finally, cones can be packed manually or automatically, depending on the level of automation of the system.

6. Advantages of using an automatic wafer making machine

- High production capacity: up to 3,000–10,000 cones per hour.

- Consistency and uniformity: all cones are the same size and thickness.

- Labor cost reduction: less staff required.

- Low energy consumption: improved thermal efficiency.

- Easy maintenance: removable and corrosion resistant components.

- Control digital: PLC panel adjusting temperature, speed and time.

- Versatility: allows you to manufacture cones of different sizes and shapes.

7. Typical technical parameters

| Model | Ability (Cones/hour) | Number of molds | Energy consumption (kW) | Weight (kg) | Dimensions (mm) |

|---|---|---|---|---|---|

| DT-CN40 | 2.000–3.000 | 40 | 15 | 800 | 1500×1200×1500 |

| DT-CN60 | 4.000–6.000 | 60 | 20 | 950 | 2000×1500×1600 |

| DT-CN120 | 8.000–10.000 | 120 | 35 | 1200 | 2600×2000×1800 |

(Indicative data according to standard configurations from manufacturers such as DT Food Machine.)

8. Applications and types of cones produced

With a industrial ice cream cone making machine, different types of wafers can be made:

- Classic cones (waffle or cookie type)

- Sugary cones with honey or cocoa flavor

- mini cones for tastings or children's products

- Flat or decorative cones for gourmet desserts

- Chocolate dipped cones or customized with logos

This versatility allows us to serve both the artisanal and industrial markets..

9. How to Choose the Best Ice Cream Cone Maker

When investing in a machine of this type, several factors must be considered:

- Production capacity: according to the desired daily volume.

- Automation level: manual, semi-automatic or automatic.

- Construction material: preferably stainless steel 304.

- Energy source: gas or electric, according to local availability.

- Maintenance and spare parts: ease of cleaning and technical support.

- Certifications: CE, ISO or others that guarantee quality and safety.

Choose a reliable manufacturer like DT Food Machine can make the difference between efficient production and a process full of complications.

10. Maintenance and cleaning

Proper maintenance extends the life of the equipment. Best practices include:

- Clean the baking plates after each day.

- Periodically check the temperature sensors.

- Lubricate moving parts according to manufacturer's instructions.

- Keep the control panel dry and free of dust.

- Use only original spare parts to avoid mechanical damage.

11. Investment and profitability

Invest in one automatic ice cream cone making machine represents a profitable opportunity. An estimated calculation shows that the production cost per cone may be less than 0.02 USD, while the average sales price is around 0.10 USD or more, depending on the market.

Besides, the return on investment (ROI) is usually achieved in 3 a 6 months, thanks to the high demand for wafers in hot seasons and the expansion of the artisanal and industrial ice cream market.

12. the importance of a modern cone machine

The ice cream cone making machine It is an essential tool for any business seeking to produce quality wafers efficiently.. Whether in a craft or industrial environment, These equipment guarantee productivity, uniformity and profitability.

Models like those of DT Food Machine combine advanced technology, durable materials and ease of use, becoming the preferred choice for manufacturers around the world. With the right choice, Your ice cream business will be able to offer irresistible products and increase your production capacity without sacrificing quality..