Introduction to peanut cream processing

The Machine for peanut cream Modern food industry has revolutionized. With the growth in the demand for healthy products, peanut butter (or peanut cream) It has become an essential food, both in local and international markets. This article offers an exhaustive guide on how to choose, operate and optimize the use of a Machine for peanut cream, Ideal for factories, entrepreneurs and distributors.

1. What is a machine to make peanut cream?

A Machine for peanut cream It is an industrial or semi -industrial equipment designed to grind roasted peanuts until you get a homogeneous and creamy paste. This type of machinery can vary in capacity, Automation level and additional function, as mixed, packaging or pasteurization.

1.1 Main function

- Fine peanut.

- Emulsion of natural peanut oils.

- Continuous production or batch.

1.2 Machine Types

- Manual or small scale.

- Semi -automatic.

- Large capacity automatic.

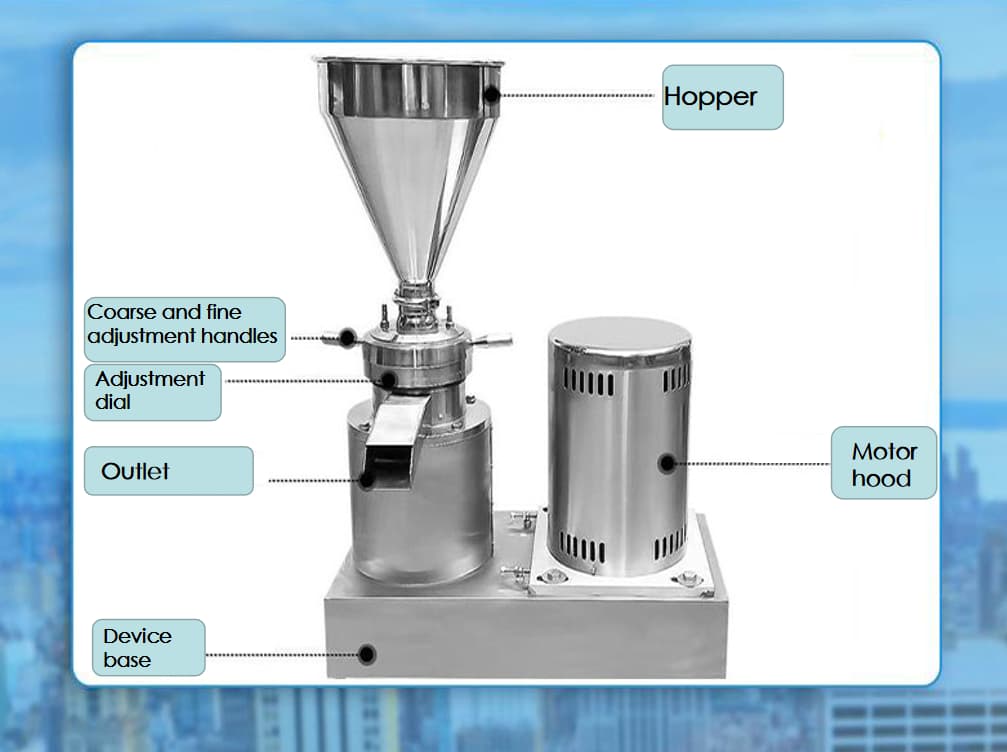

2. Components of a machine to make peanut cream

2.1 Power hopper

Container where roasted peanuts are placed.

2.2 Grinding system

Equipped with high hardness disks or stones to obtain a uniform cream.

2.3 Drive motor

Electric motor (Single -phase the three -phase) that activates the grinding system.

2.4 Stainless steel structure

Guarantees food hygiene and durability.

2.5 Temperature control

Allows to maintain product fluidity during the process.

3. Machine production process for peanut cream

3.1 Peanut selection

- Peanut without peel, No defects or excessive humidity.

3.2 Toasted

- Intensifies the taste and reduces moisture.

- It is performed in rotary or tray ovens.

3.3 Cooled

- Important before crushed to avoid overheating.

3.4 Machine with the machine

- The peanut is introduced into the machine to reduce until you get a soft cream.

3.5 Mixture of additives (optional)

- Sugar, sal, Accept vegetable to stabilizers.

3.6 Packing

- Automatic the manual, in glass or plastic bottles.

4. Advantages of using a machine to make industrial peanut cream

- High efficiency and production capacity.

- Total control over product texture.

- Less labor.

- Cross contamination reduction.

- Improvement in product useful life.

5. Applications of peanut cream produced

- Food industry (untables, dessert, Energy bars).

- Export.

- Direct sale to the final consumer.

- Institutional use (schools, hospitals, prisons).

6. Common technical parameters

| Model | Ability (kg/h) | Power (kW) | Voltage | Weight (kg) | Material |

|---|---|---|---|---|---|

| DT-50 | 50 | 1.5 | 220V | 55 | Stainless steel 304 |

| DT-100 | 100 | 3.0 | 380V | 75 | Stainless steel 304 |

| DT-200 | 200 | 5.5 | 380V | 110 | Stainless steel 304 |

| DT-500 | 500 | 11 | 380V | 300 | Stainless steel 316 |

7. How to choose the best machine to make peanut cream?

7.1 Daily production

Choose an appropriate model to your estimated volume (50 kg/day 1000 kg/day).

7.2 Client type

- For entrepreneurs: Compact or laptops.

- For factories: Automatic lines with conveyor belt and pasteurizer.

7.3 Budget

- Basic models: From USD $800.

- Industrial: USD $5,000 – $25,000.

8. Complete peanut cream production line

An industrial line includes:

- Peanuts

- Toastering machine

- Cooler

- Machine for peanut cream

- Mix tank

- Filling and Sealing System

9. MAINTENANCE OF THE MACHINE TO MAKE CACAHUATE CREAM

9.1 Daily cleaning

- After each lot, Was with hot water.

- Avoid waste to prevent fermentation.

9.2 Lubrication

- Check weekly mobile parts.

9.3 Electrical inspection

- Ensure ground connection.

- Check overloads.

10. Operating costs and profitability

10.1 Costs

- Peanut: $1.2/kg

- Electricity: $0.10/Kg processed

- Maintenance: $100/mes

10.2 Sale price

- Local market: $3.5 – $6/kg

- Gourmet export: $8 – $12/kg

10.3 Estimated ROI

- Return in 3-6 months with constant production.

11. Success cases in Latin America

11.1 Mexico

Small handmade factories in Puebla and Oaxaca already produce more than 2 TONS MONTHLY.

11.2 Colombia

Companies that export organic cream to the US.

11.3 Peru and Ecuador

Regional brands supply supermarket chains and pharmacies.

12. REQUIRED REGULATIONS AND CERTIFICATIONS

- HACCP

- ISO 22000

- Local standards (SENASA, Invima, COFEPRIS)

- Export certifications: FDA, USDA

13. Frequently asked questions (FAQ)

Can I use the same machine for other nuts?

Yeah, With adjustments it can be used for almond, nut, anacard.

Does the machine need specialized operator?

No, It is easy to use after a brief training.

How long does a machine make to make peanut cream?

Between 8 y 15 years, depending on the use and maintenance.

How many kg/h can process a medium machine?

Approximately 100 a 200 kg/h.

14. Tips for entrepreneurs

- Perform taste and texture tests before climbing production.

- Use attractive labels.

- Promote nutritional benefits.

- Includes chocolate variants, Miel The Cinnamon.

15. Conclusion

The Machine for peanut cream It is the ideal team for those who seek to undertake or expand their productive capacity in the food sector. Your versatility, Ease of operation and demand in constant growth makes it an intelligent investment. Either on a small scale or at the industrial level, This technology allows to offer a nutritional product, tasty and highly profitable.