The ice cream industry not only depends on a delicious recipe, but also of a perfect presentation. And in this sense, Cucuruchos or ice cream cones They are the essential complement. For companies that wish to climb their production efficiently, invest in one Industrial Cucuruchos Machine It is a strategic decision. In this article, We present everything you need to know about these machines: How they work, its types, benefits and how to choose the most appropriate for your business.

Cucuruchos industrial manufacturer: What is and how works?

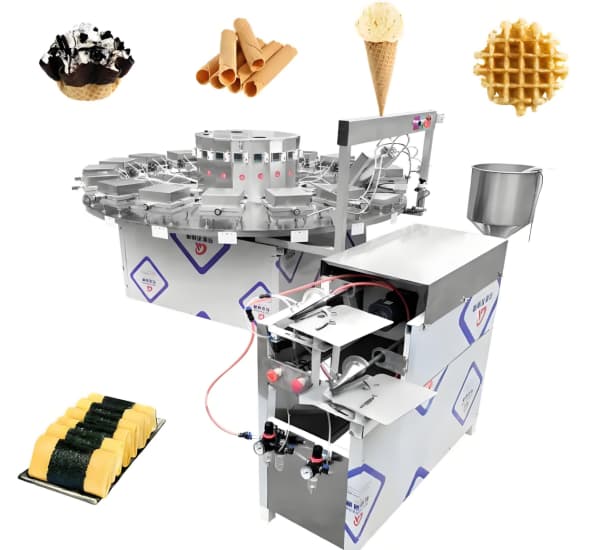

A Cucuruchos industrial manufacturer It is an automated machine designed specifically to produce large volumes of ice cream cones. Use hot molds that receive a special liquid mass that, When heating, It becomes a crispy cracking ready to cool and pack.

The basic process includes:

- Automatic massification.

- Cooking between heated plates.

- Cucurucho molding.

- Automatic cooling and stacking.

Thanks to its high degree of automation, These machines allow continuous production, consistent and with minimal losses.

Automatic ice cream cones: High efficiency and under margin of error

The Automatic ice cream cones represents a modern solution for manufacturers looking for speed and precision. These machines can produce between 3,000 y 10,000 Cucuruchos per hour, depending on the model and configuration.

Key advantages:

- Continuous production: Ideal for factories with high demand.

- Intelligent Temperature Control: ensures the ideal texture of the cone.

- Stainless steel hygienic design: easy to clean and maintain.

- PLC control systems: that allow rapid and precise adjustments.

Besides, Some versions have fault detection systems that alert the operator if there are interruptions, which reduces waste and improves efficiency.

Industrial teams to make cookie cucuruchos: Variety of sizes and models

One of the most prominent benefits of Industrial teams to make cookie cucuruchos It is versatility. These machines can be adapted to produce different types of cones:

- Classic cones (Sugar or wafer type).

- Mini cucuruchos For tastings.

- Jumbo cones or custom for premium ice cream shops.

- Flat cones or tulip type For special presentation.

Besides, Some machines allow changing the mold design, which is ideal for brands that want to offer a unique style.

Barquillo Cucuruchos Machine: Most important technical characteristics

The machines for barquillo cucuruchos are widely used due to the crunchy and sweet texture they achieve. Here are some Common technical specifications In industrial models:

- Structure material: stainless steel 304.

- Energy consumption: between 15kw and 30kw.

- Production capacity: of 3000 a 12,000 Cones per hour.

- Cooling systems: industrial fans or conveyor belts with forced ventilation.

- Interchangeable modules: To change cone size and design.

These teams are designed to work for several continuous hours without losing efficiency or quality.

Machine to make edible cones for ice cream: Benefits for food industry

Opt for one Machine to make edible cones for ice cream Bring multiple benefits:

1. Reduction of production costs

By automating the process, Manual errors are eliminated and the use of raw material is optimized.

2. Uniformity of the final product

Each cone is exactly the same as the previous, which improves the presentation of the product in front of the final customer.

3. Scalability

These machines allow growing in volume without significantly increasing labor.

4. Quality control

Thanks to automated systems, Each stage of the process can be monitored to meet the sanitary and quality standards.

Industrial Cucuruchos Training Machine: Adaptation to different business models

The Industrial Cucuruchos Training Machine It is not just for large factories. There are also compact versions that can be useful for medium -sized companies or ventures. There are market options that allow producing from 1,000 Cones per hour, Ideal for small plants.

Types according to capacity:

- Small model: until 2000 Cones/hour.

- Standard model: between 3000 y 6000 Cones/hour.

- High capacity model: more than 8000 Cones/hour.

You can also opt for models with different automation levels: From semi -automatic to completely automatic.

Industrial machine for barchillos: Maintenance and cleaning

One of the most important aspects when acquiring a industrial machine for barchillos It is maintenance. To ensure a long life of the equipment and avoid contamination, certain routines must be followed:

- Daily cleaning of plates and molds.

- Weekly review of electrical systems and engines.

- Periodic lubrication of moving parts.

- Verification of sensors and dosing valves.

Many modern machines already come with self -employment systems or removable parts that facilitate these tasks.

INDUSTRIAL TYPE CUCURUCHOS MACHINE: Key factors to choose the best

Before acquiring a INDUSTRIAL TYPE CUCURUCHOS MACHINE, It is important to evaluate several factors:

1. Production capacity

Evaluate how much product you need to generate per hour.

2. Cucurucho type

Not all machines serve all types of cone. Make sure you can produce the format you want.

3. Ease of use and maintenance

An intuitive control panel and easy access to internal parts are key.

4. Health certifications

Verify that the team complies with international quality and hygiene standards.

5. Technical and Spare Service

Choose brands that offer good post -sales support and spare parts available.

Where to buy an industrial cucuruchos machine: Market options

There are several options in the market to acquire these machines. Some of the most recognized brands and distributors include:

- MEC Group

- GELMATIC

- Shanghai Target Industry Co., Ltd.

- Techno-Ice

- Prawema Maschinenbau GmbH

You can also find Machines to make used industrial cucuruchos, which represents an economic option to start, provided that the state of the equipment is verified.

Conclusion: Innovation in Cucuruchos production

Invest in one Industrial Cucuruchos Machine It is much more than acquiring a equipment; is to bet on standardization, efficiency and growth of your business. Whether you manage a small artisanal plant or a mass production factory, These machines represent the bridge between the ice cream tradition and the technology of the 21st century.

With multiple models, capacities and functionalities, The market offers options for each need. The important thing is to identify which one best suits your scale, Budget and growth vision.