In the world of ice cream and candy production, los cucuruchs y Cubanitos They are irresistible products that accompany both artisanal businesses and industrial factories.. The growing demand for crispy, uniform wafers has driven the development of specialized equipment such as Cucuruchos and Cubanitos Machine, a solution that combines technology, speed and quality to optimize production and increase profitability.

We will explore in detail what a cone and cubanito making machine is., how it works, What types exist, its technical characteristics, competitive advantages and tips to choose the ideal model for your business.

1. What is a Machine to Make Cones and Cubanitos??

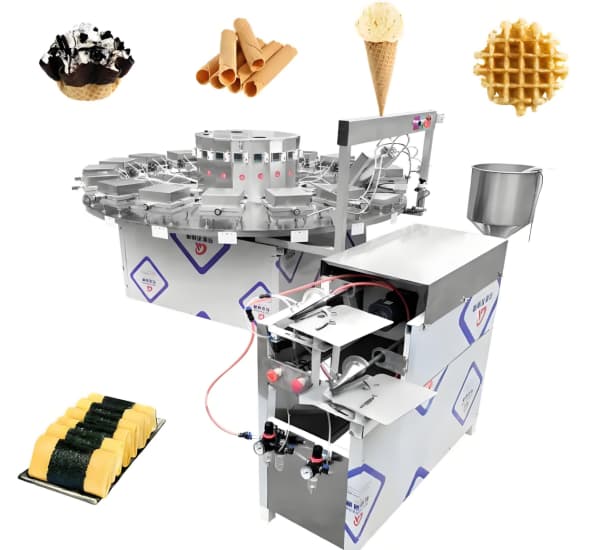

A Cucuruchos and Cubanitos Machine is a piece of equipment designed to automatically or semi-automatically produce the traditional wafers o ice cream cones, as well as the Cubanitos, which are sweet and crunchy rolls made with a dough similar to that of cones.

Its main function is cook, roll and form the wafers with precision, guaranteeing uniform texture, golden color and delicate flavor. This type of machinery can adapt to different production scales: from small artisanal businesses to large-capacity industrial plants.

Among the most common names with which this type of machine is known we find:

- Ice cream cone making machine

- Automatic machine to make cubanitos

- Professional waffle maker

- Industrial machine to make cones and cubanitos

- ice cream cone production equipment

2. How does a Machine to Make Cones and Cubanitos work??

The operation of a machine of this type is a continuous process controlled by temperature and time systems.. Broadly speaking, The manufacturing process of cones or cubanitos includes the following stages:

a) MIX PREPARATION

A liquid flour-based dough is prepared, sugar, oil and water. This mixture should have a smooth and uniform texture to ensure even cooking..

b) Firing the sheets

The machine has cooking plates (usually made of stainless steel or cast iron with non-stick coating) They cook the mixture until they obtain a thin, golden foil..

c) Molding

Immediately after cooking, The still hot sheets are rolled or molded with rollers or metal cones, depending on whether they are going to be manufactured cucuruchs (conical shape) o Cubanitos (cylindrical shape).

d) Cooling and stacking

The wafers are cooled on a conveyor belt or in special trays, retaining its shape and crispy texture. Finally, are stacked and packaged for distribution or sale.

3. Types of Machines for Making Cones and Cubanitos

Depending on the level of production and automation, There are several types of machines:

a) Manual or semi-automatic machines

Ideal for small businesses or artisanal ice cream shops. These machines allow you to manually control cooking and rolling.. Although its production is more limited, offer flexibility and low cost.

b) Automatic machines

These machines integrate the entire process: from pouring the mixture to forming and stacking the cones. They have PLC systems, touch screens and automatic temperature control. They can produce between 1000 y 5000 Units per hour, Depending on the model.

c) High capacity industrial machines

Designed for large-scale production plants, These machines work continuously, with multiple baking molds, motorized winding systems and automatic cooling units. They are perfect for companies that distribute wafers or cubanitos nationally or internationally..

4. Main Technical Features

Next, We present an example of technical specifications of a automatic machine to make cones and cubanitos:

| Parameter | Standard specification |

|---|---|

| Production capacity | 1500 – 5000 pieces/hour |

| Structure material | Stainless steel 304 |

| Cooking type | Electric or gas |

| Control | PLC + touch screen |

| Cone diameter | 45 – 120 mm (adjustable) |

| Cubanito length | 70 – 120 mm |

| Power | 15 – 30 kW (According to model) |

| Weight | 800 – 1500 kg |

| Dimensions | 2500 × 1500 × 1800 mm |

| Energy consumption | Low consumption, with heat recovery system |

These machines are designed to offer high precision, energy efficiency and durability. Besides, The use of stainless steel components ensures a hygienic environment, suitable for the food industry.

5. Advantages of Using a Machine to Make Cones and Cubanitos

a) Greater productivity

Allows thousands of units to be manufactured per hour, optimizing time and reducing labor costs.

b) Product uniformity

Each wafer or cubanito maintains the same shape, size and color, guaranteeing constant quality.

c) Temperature and cooking control

Automatic control systems prevent overheating and ensure perfect cooking.

d) Low maintenance

Most modern machines are designed to operate continuously with easy cleaning and minimal intervention..

e) Energy savings

The new generation models have thermal efficiency systems that reduce electricity or gas consumption.

f) Compliance with health standards

Made with stainless steel and food grade materials, They comply with international hygiene and safety regulations.

6. Commercial Applications

Las machines to make cones and cubanitos are widely used in:

- Industrial wafer factories

- Artisanal and commercial ice cream parlors

- Bakeries and confectioneries

- Snack and dessert industries

- Frozen food or packaged candy companies

These machines are not only limited to use in ice cream parlors, but they are also used by companies that sell cubanitos filled with chocolate, cream or dulce de leche, increasing product diversity and business opportunities.

7. Tips for Choosing the Right Machine

If you are considering investing in a Cucuruchos and Cubanitos Machine, We recommend that you take into account the following factors:

- Desired production volume: define if you need a manual machine, semiautomatic the totally automatic.

- Energy source: choose between electric or gas models based on availability in your region.

- Product size: Make sure the machine can adjust the diameter and length of the cucurucho or cubanito.

- Ease of cleaning and maintenance: a stainless steel machine makes daily hygiene easier.

- Technical support and spare parts: choose a manufacturer with experience and reliable after-sales service.

- Quality certifications: look for equipment with CE certifications, ISO or equivalents.

8. Innovation and Technology in Modern Machines

The most advanced manufacturers, as DT Food Machine, have integrated cutting-edge technology into their lines of machines to make cones and cubanitos, including:

- Intelligent PLC control systems that allow you to adjust temperature, cooking time and rolling speed.

- Modular designs that facilitate the expansion of productive capacity.

- Complete automation of the mixing process, cooking, rolled and stacked.

- Thermal efficiency enhanced by waste heat recovery.

- Food security through hygienic surfaces and corrosion-resistant components.

These innovations guarantee not only a efficient production, but also a final product of excellent quality and presentation.

9. Machine Maintenance and Cleaning

Preventive maintenance is essential to extend the life of the machine. Some recommendations include:

- Clean the hobs at the end of each day.

- Periodically check the temperature sensors.

- Lubricate moving parts according to manufacturer's instructions.

- Avoid using metal tools that could damage non-stick surfaces..

- Carry out a general inspection every six months.

Proper maintenance ensures stable operation and reduces unplanned downtime.

10. Investment and Profitability

Investment in a Cucuruchos and Cubanitos Machine can recover quickly thanks to high demand for the product and low cost of raw materials.

For example, with a machine that produces 3000 Units per hour, and considering a low production cost, Return on investment can be achieved in a few months, especially if the product is distributed to ice cream parlors, bakeries or supermarkets.

Besides, the possibility of customize sizes and flavors (vanishing, chocolate, strawberry, caramel) allows you to diversify the offer and increase profitability.

Cucuruchos and Cubanitos Machine

The Cucuruchos and Cubanitos Machine represents an essential tool for any business seeking to enter or expand in the candy and ice cream market.. With its automation capacity, energy efficiency and precise control, This machine offers a perfect balance between productivity and quality.

Whether for a industrial factory or one artisanal ice cream parlor, Investing in a machine of this type guarantees uniform products, crispy and delicious, ready to conquer the palate of consumers.

If you are looking for a high quality machine, reliable and adapted to your needs, DT Food Machine is a leading manufacturer with experience in design and production of cone making machines, cubanitos and industrial wafers, providing complete solutions from engineering to installation and technical support.

Related keywords:

wafer making machine, ice cream cone machine, automatic cucuruchos machine, industrial cubanitos making machine, professional wafer machine, ice cream cone making machine, equipment to make cubanitos, stainless steel wafer machine.