The MACARONS MACHINE It is an essential team in the food industry, especially for the production of short quality pasta. In this article more than 2500 words, We will explore in depth every aspect of these machines: From its variants and technical characteristics to installation recommendations, MAINTENANCE AND OPTIMIZATION OF THE PROCESS.

Index

- INTRODUCTION TO THE MACARONS MACHINE

- Types of macaroni machine

- 2.1. Automatic industrial macaroni machine

- 2.1.1. Characteristics of the extrusora for macaroni with PLC system

- 2.1.2. Advantages of the automatic line of high capacity macaroni

- 2.2. Semiautomatic cutting extruder

- 2.2.1. Modular design and ease of cleaning

- 2.2.2. Flexibility in change of molds and formats

- 2.1. Automatic industrial macaroni machine

- Technical parameters of the machine to make macaroni

- MACARONES PRODUCTION PROCESS

- 4.1. Preparation of the mass mixture

- 4.2. Extrusion and cut of macaroni

- 4.3. Drying and packaging

- Installation and commissioning

- 5.1. Space and energy requirements

- 5.2. Electrical and water connections

- Preventive maintenance and cleaning

- 6.1. Component lubrication and verification plan

- 6.2. Hygiene protocols according to food safety standards

- Optimization and Continuous Improvement

- 7.1. Temperature and humidity control

- 7.2. Parameter setting for different types of flour

- Success cases and purchase recommendations

- Conclusions

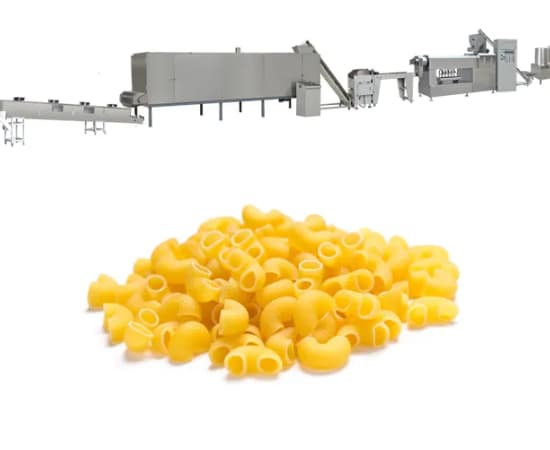

INTRODUCTION TO THE MACARONS MACHINE

The MACARONS MACHINE It is essential for any pasta production plant that seeks constant efficiency and quality. Thanks to the automation and precise control of parameters such as pressure and temperature, These machines allow macaroni continuously and with uniform characteristics.

Currently, There are various technologies that cover from small handmade productions to large -scale industrial plants. Through this guide you will learn to distinguish between different options and implement good practices to maximize the performance and safety of your production line.

Types of macaroni machine

There are mainly two large categories of macaroni machines:

Automatic industrial macaroni machine

Las automatic industrial macaroni machines They are designed for large volumes, With automation systems (PLC, HMI) that facilitate operation and continuous monitoring.

Characteristics of the extrusora for macaroni with PLC system

- Control PLC/HMI: Allows you to program production recipes, Adjust extrusion pressure and speed.

- High -power engine: Engine of 15 kW a 30 kW to guarantee a constant mass flow.

- Stainless steel structure 304: Complies with FDA and CE standards.

Advantages of the automatic line of high capacity macaroni

- Continuous production until 1000 kg/h.

- Integration with tunnel drying systems and automatic packaging.

- Lower manual intervention, which reduces human error and improves hygiene.

Semiautomatic cutting extruder

For medium or handmade productions, las semi -automatic extruders They offer flexibility and lower investment cost.

Modular design and ease of cleaning

- Removable components that facilitate washing and disinfection.

- Rapid changes of molds and screws without the need for specialized tools.

Flexibility in change of molds and formats

- Interchangeable molds for smooth macaroni, striated, elbows and other forms.

- Manual extrusion speed adjustment for different diameters.

Technical parameters of the machine to make macaroni

Next, A type table with the Technical parameters more relevant for an automatic industrial macaroni machine:

| Parameter | Specification |

|---|---|

| Production capacity | 500–1000 kg/h |

| Motor power | 18 kW |

| Voltage | 380 V / 50 Hz |

| Extrusion temperature | 30–80 °C |

| Working pressure | 0.6–1.5 MPa |

| Construction material | Stainless steel 304 |

| Control | PLC with HMI touch screen |

| Dimensions (L×A×H) | 4500 × 1200 × 1800 mm |

| Weight | 2000 kg |

Tabla 1. Automatic machine technical parameters to make macaroni.

MACARONES PRODUCTION PROCESS

The process consists of three main phases:

Preparation of the mass mixture

- Dosage of flour and water: Typical proportion 100 kg of flour for 30–40 liters of water.

- Kneaded: In independent chamber or mixer to obtain homogeneity.

- Repose: 5–10 minutes to improve plasticity.

Extrusion and cut of macaroni

- Mass: It is introduced into the hopper of the extruder.

- Extrusion: The dough passes through the screw and mold, acquiring the desired form.

- Cut: Adjustable rotary blade for lengths between 10–60 mm.

Drying and packaging

- Tunnel drying: Temperature of 40–60 ° C, Controlled humidity 30–45 %.

- Cooled: Temperature reduction before packaging.

- Packing: Automatic Manual, With polyethylene film or paper bags.

Installation and commissioning

The correct installation guarantees optimal and safe operation.

Space and energy requirements

- Minimum space: 6 × 4 m for full line.

- Electrical connections: 380 V / 50 Hz, Three -phase line with the capacity to 25 A.

Electrical and water connections

- Water outlet: ½” with minimal pressure 2 bar.

- Drainage: Gutter or sink for washing waste.

Preventive maintenance and cleaning

A maintenance plan reduces stops and lengthens the useful life.

Component lubrication and verification plan

- Great of bearings each 200 Operation hours.

- Belly and pulley review monthly.

Hygiene protocols according to food safety standards

- Daily cleaning with hot water (>60 °C) and authorized detergents.

- Weekly sterilization with hypochlorite solution to the 200 ppm.

Optimization and Continuous Improvement

Continuous improvement maximizes efficiency and quality.

Temperature and humidity control

- Online sensors to adjust real -time parameters.

- Data registration and lot traceability.

Parameter setting for different types of flour

- Sémolo VS Flour Flour: variation in water absorption and drying time.

- Pilot tests to calibrate pressure and temperature.

Success cases and purchase recommendations

XYZ Factory (Space): Production increase in 30 % After the automatic line installation of 800 kg/h.

Recommendations:

- Select manufacturers with ISO-22000 certifications.

- Evaluate after -sales service and availability of spare parts.

Conclusions

The choice of MACARONS MACHINE Adequate depends on the volume of production, budget and quality requirements. With technical information and good practices presented, You can make informed decisions and optimize your production line to guarantee top -level products.