To meet this huge demand, Companies need to have the potato chip making machine adequate. This equipment not only determines production capacity, but also the final quality of the product, efficiency in the use of resources and, of course, business profitability.

In this article we will explore in depth what a potato chip making machine is., its characteristics, the types available, the factors that influence its price, The production process, Tips for choosing the right equipment and future industry trends.

1. What is a potato chip making machine??

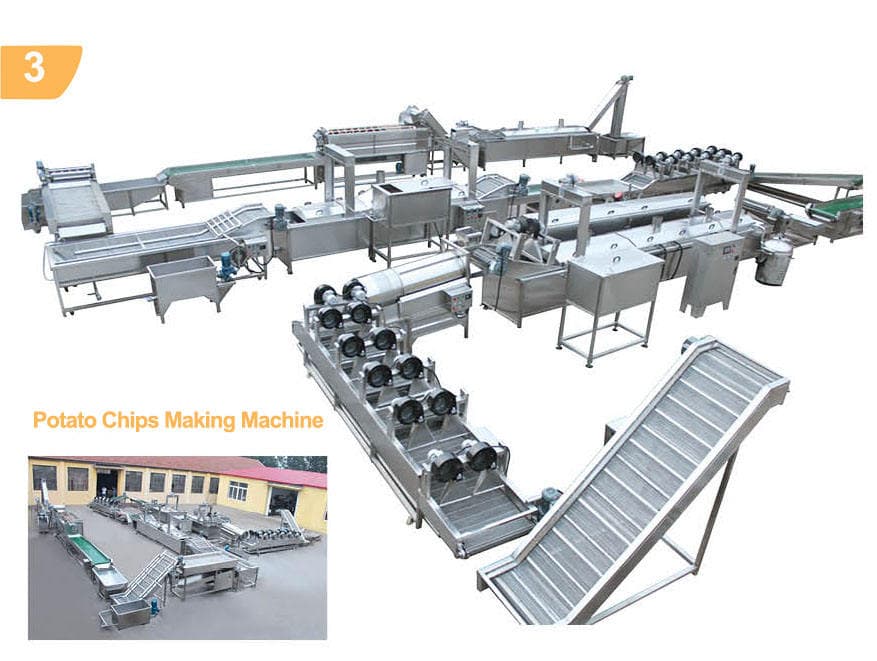

A potato chip making machine is a set of industrial equipment designed to transform fresh potatoes into crispy chips ready for packaging and distribution. Although it is called “machine” in the singular, In reality it is usually a production line composed of several stages:

- Washing and peeled: Impurities and skin of the potatoes are removed.

- Cut into thin slices: Potatoes are sliced with uniform thicknesses.

- Bleached: Color is stabilized and excessive starches are eliminated.

- Surface drying or dehydration: To avoid excess oil absorption.

- Frying: In oil at controlled temperature to achieve crispy texture.

- Defatted and cooled: Removal of excess oil.

- Seasoned: flavors are added (sal, queso, barbecue, etc.).

- Packing: Sealed in airtight bags to ensure freshness.

Each of these phases can be carried out with independent machines or within a fully automatic line..

2. Importance of the potato chip making machine

- Quality consistency: Allows each chip to be the same thickness, color and texture.

- Time and cost savings: Process large volumes in fewer hours and with less labor.

- Hygiene and food safety: Being made of food grade stainless steel, avoid contamination.

- Profitability: With a good machine, Return on investment can be achieved in months.

3. Types of potato chip making machines

3.1. According to the level of automation

- Semi-automatic: Require more manual intervention, recommended for small productions (100–200 kg/h).

- Automatic: Control digital, require fewer workers, ideal for medium and large factories (300–1000 kg/h or more).

3.2. According to production capacity

- Small scale (100 kg/h): For entrepreneurs or local businesses.

- Median scale (300–500 kg/h): For regional distributors.

- Large scale (1000 kg/h or more): For export and international industries.

3.3. Depending on the type of chips produced

- Traditional fried chips.

- Low-fat chips with vacuum frying technology.

- baked chips.

4. Factors that influence the price of the potato chip making machine

- Production capacity: A greater capacity, higher price.

- Automation level: Automatic lines cost more, but they save on labor.

- Materials: stainless steel 304/316 raise the price, but guarantees durability.

- frying technology: Conventional, continuous or vacuum.

- Energy saving systems: More efficient machines have a higher initial cost, but reduce operating expenses.

- Country of manufacture and brand: Recognized suppliers usually have higher prices, but better technical support.

5. Estimated price of potato chip making machines

| Ability | Type | Price range (USD) | User profile |

|---|---|---|---|

| 100 kg/h | Semi-automatic | 5,000 – 15,000 | small businesses |

| 300 kg/h | Partial automatic | 15,000 – 35,000 | SMEs |

| 500 kg/h | Full automatic | 35,000 – 60,000 | Medium factories |

| 1000 kg/h | Industrial automation | 60,000 – 120,000 | Large industries |

(Prices vary depending on provider, materials and customization.)

6. Step by step production process

An example with a line 500 kg/h:

- They are introduced fresh potatoes in the roller washing machine.

- They go to abrasive peeler, removing the skin.

- The automatic cutter converts them into thin sheets.

- Bleach controls the enzyme that darkens the product.

- Air dryer removes excess water.

- The continuous fryer cooks them at 170-180°C.

- Centrifugal degreaser reduces the amount of oil.

- Seasoning drum adds flavor.

- Finally, They are packaged in airtight bags ready for sale.

7. Investment return (ROI)

Example with 500 kg/h:

- Raw potato cost: 0,30 USD/kg

- Chip sales: 3,00 USD/kg

- Conversion: 1 kg papa → 0,35 kg chips

- Daily production (8h): 1.400 kg chips

- Estimated income/day: 4.200 USD

- Net profit/day: 1.000–1.200 USD

👉 With this calculation, The investment of the machine can be recovered in 6 a 12 months.

8. Tips for choosing the right machine

- Define the output expected.

- Check materials (stainless steel 304).

- Compare energy costs (electric, gas, diesel).

- Evaluate the after-sales support from the manufacturer.

- Consider the space available in the plant.

- Ask about options personalization (flavors, packing).

9. Trends in the potato chip industry

- Vacuum frying technology for healthier chips.

- Low energy consumption systems to reduce costs.

- Digitalization and IoT for real -time monitoring.

- Sustainable packaging that extend useful life and reduce environmental impact.

10. Chips Potato Machine

The potato chip making machine It is a strategic investment for any company that wants to enter or expand in the snacks market.. From small artisanal productions to large industrial factories, There is a solution adapted to every need and budget.

Choosing the right equipment ensures not only product quality, but also cost efficiency and long-term profitability.

11. Recommendation: DT Food Machine

In DT Food Machine We are manufacturers and suppliers specialized in potato chip making machines and complete production lines. Our equipment is made of food grade stainless steel, They feature advanced automation systems and offer reliable performance in any production environment..

Whether you need a machine 100 kg/h to start your business or one industrial line of 1000 kg/h for large scale production, in DT Food Machine you will find the best solution with competitive prices, installation, training and professional technical support.

👉 DT Food Machine: Your reliable partner in potato chip making machines.