Pasta machine

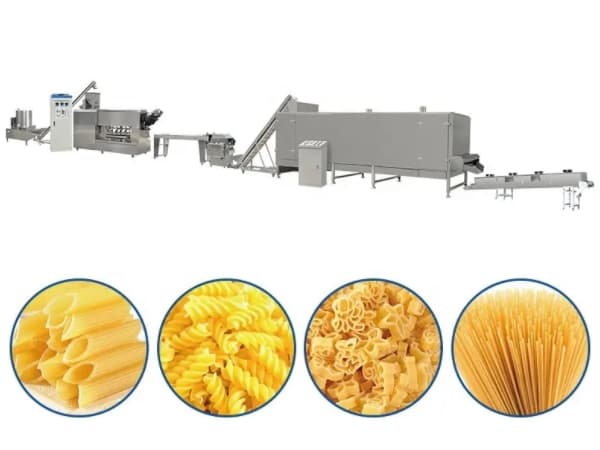

The Pasta machine It is an essential team for efficient pasta production at an industrial or commercial level. Designed to automate the process, It allows to elaborate a wide variety of formats like spaghetti, fettuccine, penne, macaroni and more.

This type of machine integrates functions such as mixed, extrusion, cut and, optionally, Drying. Thanks to its stainless steel structure, It complies with high standards of hygiene and durability.

Available in different capacities, from 100 kg/h to 5 tons per hour, It adapts easily to the needs of small factories, medium or large.

Besides, Its intuitive operation system reduces the need for labor, optimizing production costs.

It is the ideal solution for those looking for quality, speed and uniformity in the elaboration of pasta.

Pasta machine

Pasta dough mixer

Pasta production begins with a MASS MIXER efficient. This machine is responsible for combining flour, water and in some cases eggs or other ingredients according to the desired type of pasta.

The internal pallets or propeller system guarantees a homogeneous and lump -free mixture, essential to obtain an elastic and well hydrated mass. The quality of this phase determines the texture and taste of the final product.

A good pasta machine must always start with a professional mixer, ensuring uniformity and performance in the rest of the process.

Industrial Pasta Amazadora

After the mixture, The dough goes to the Pasta kneading, whose function is to work the mixture to obtain a firmer texture, developing gluten properly.

This process helps eliminate excess air and provides elasticity, which improves extrusion or posterior laminate. In larger production lines, The kneader can be continuous and automated.

This step is vital on the pasta machine, since a well kneaded mass allows a more defined way and a uniform cooking.

Pasta laminator

The prepared dough is introduced into the Pasta laminator, where he flattened and stretches in fine and uniform sheets, ready to be cut or filled.

The machine allows you to adjust the thickness of the sheet according to the type of pasta, From Lasañas to Raviolis. The smooth and continuous roller system ensures a even stretch, Without breaks or bubbles.

It is an essential component in any paste machine, especially for high quality fresh or handmade pasta lines.

Pasta Cutter Machine

Once laminated, The dough passes through the Pasta Cutter Machine, that shapes spaghetti, fettuccine, noodles and other types of long or short paste.

By rotating blades or interchangeable molds, This machine allows to obtain a wide variety of formats with clean and precise length cuts. Creative forms can also be incorporated.

The cutter is a key part of every machine to make pasta, since it defines the final aspect of the product and allows to adapt the production to the market demands.

Folder extruder machine

For pasta like macaroni, Fusilli or Penne, One is used folder extruder machine. This pushes the dough through specific molds, forming by controlled pressure.

Extrusora is ideal for industrial production, since it allows large volumes with precision. Besides, maintains product integrity without altering its taste or texture.

Inside the pasta machine, The extruder expands the range of products available, being essential for factories seeking versatility.

Industrial pasta dryer

After cutting or extrusion, Pasta must be dried to ensure conservation. The industrial pasta dryer Apply hot air in scheduled cycles, reducing moisture without damaging the product.

The drying process is essential to avoid molds, Maintain color and improve the final texture. Advanced models allow to adapt the temperature and time to the type of pasta.

This step is essential in the pasta machine, especially when dry pasta is produced for sale in supermarkets or export.

Paste packaging machine

The last step in the line is the paste packaging machine, that protects the product and presents it ready for sale. Can work with vacuum containers, Flowpack or sealed trays.

In addition to packaging, Many machines include functions such as labeling, Lot coding and weight control. This facilitates traceability and improves brand image.

It is a key component of the pasta machine, ensuring that product quality reaches the final consumer intact.

Technical specifications and machine capacity to make pasta

| Parameter | DT-100 | DT-500 | DT-1000 | DT-3000 | DT-5000 |

|---|---|---|---|---|---|

| Production capacity | 100 kg/h | 500 kg/h | 1000 kg/h | 3000 kg/h | 5000 kg/h |

| Total power installed | 5.5 kW | 12 kW | 18 kW | 35 kW | 50 kW |

| Voltage | 220V / 380V | 380V / Three-phase | 380V / Three-phase | 380V / Three-phase | 380V / Three-phase |

| Type of compatible paste | Cut, long | Cut, long, Fill | Cut, long, Fill | Varied industrial | Varied industrial |

| Construction material | Acero Inox. AISI 304 | Acero Inox. AISI 304 | AISI 304/316 | AISI 304/316 | AISI 304/316 |

| Dimensions approx. | 1.8 × 0.8 × 1.6 m | 2.8 × 1.2 × 2.0 m | 3.5 × 1.5 × 2.2 m | 6.5 × 2.5 × 3.0 m | 8.5 × 3.0 × 3.5 m |

| Net weight | 300 kg | 800 kg | 1200 kg | 2800 kg | 3800 kg |

| Control system | Manual o digital simple | PLC + touch screen | PLC + touch screen | PLC + SCADA | PLC + SCADA |

| Drying time | 6–8 hours | 6–8 hours | 4–6 hours | 3–5 hours | 3–5 hours |

| Drying temperature | 40 °C – 90 °C | 40 °C – 90 °C | 40 °C – 90 °C | 40 °C – 90 °C | 40 °C – 90 °C |

| Automation level | Semi -automatic | Partial automatic | Fully automatic | Fully automatic | Fully automatic |

| Number of operators | 1 persona | 1–2 personas | 2–3 personas | 3–5 personas | 5–7 personas |

| Certifications | CE, ISO 9001 | CE, ISO, HACCP | CE, ISO, HACCP | CE, ISO, HACCP | CE, ISO, HACCP |

| Cleaning system | Manual | Manual / Optional CIP | Semi-automatic CIP | Automatic CIP | Automatic CIP |

| Energy Consumption Approx. | 4 kWh | 9–11 kWh | 14–18 kWh | 25–32 kWh | 38–50 kWh |

All our machines comply with international quality and safety regulations, guaranteeing efficient and safe functioning.

Rfq- Pasta machine

1. What is the production capacity available for the machine to make pasta?

🟢 Answer:

We offer capabilities from 100 kg/h to 5000 kg/h, covering artisanal production needs to industrial. We can customize according to your exact requirement.

2. Can the machine produce different types of pasta?

🟢 Answer:

Yeah. Our machines can manufacture short dough (macaroon, penne), wide pasta (spaghetti, noodles) y stuffed paste (ravioli, tortellini), depending on the model and molds.

3. What is the manufacturing material of the machine?

🟢 Answer:

We use stainless steel AISI 304 For all parties in contact with food. For industrial lines, We also offer AISI 316 Under request.

4. Is it easy to clean and maintain?

🟢 Answer:

Yeah. Machines have hygienic design, smooth surfaces and options for CIP cleaning (Clean in Place) In automatic models. Manual in small models.

5. Does it include pasta drying system?

🟢 Answer:

Yeah. We offer full lines with controlled drying tunnels, adjustable between 40–90 °C, with drying times between 4–8 hours, According to the type of pasta.

6. What level of automation do they offer?

🟢 Answer:

We have models semi -utomatics, partial automatic And totally automated with PLC and touch screens, adapted to your budget and operation.

7. What electric power does the machine need?

🟢 Answer:

It depends on the model. It goes from 5.5 kW (to 100 kg/h) until 50 kW (to 5000 kg/h). They all operate with 380In Trifasico, But we offer 220V versions on request.

8. How many workers are required to operate the machine?

🟢 Answer:

For small models, Enough with 1 operator. Industrial lines require between 2–7 personas, Depending on the automation level.

9. Do they offer installation and training service?

🟢 Answer:

Yeah. We provide INSTALLATION IN SIT, Manual in Spanish/English, y Technical training in -person u online. We also give post -sales support 24/7.

10. Can the machine be customized according to our needs?

🟢 Answer:

Of course. We can Customize molds, voltage, size, Production speed, Type of pasta and automation level according to their specific requirements.

Machine manufacturers for pasta

We are one of the Main machine manufacturers for pasta In China, With more than 15 Years of experience in the food machinery industry. Our factory is equipped with advanced technology, Highly qualified technical staff and strict quality controls, which allows us to offer safe pasta production solutions, efficient and personalized for each client.

Why choose us? First of all, Our pasta machines are completely manufactured in Food grade stainless steel (AISI 304), guaranteeing hygiene and durability. Second, we offer Complete production lines, From mixing, extrusion, court, Drying up to packaging. Third, We provide Global after -sales service, including installation, Online technical training and support.

Besides, We adapt our equipment according to the production capacity you need, from 100 kg/h to 5 tons/hour, and we offer custom designs for different types of pasta: spaghetti, macaroni, ravioli, penne, among others. Our mission is to help each client create their own pasta brand efficiently, quality and lower production cost.

Choosing us is choosing quality, experience and commitment.

Machine price for pasta

He Price of a pasta machine varies according to production capacity, the level of automation and the components included in the line. For example, a small machine for industrial use with the capacity to 100 kg/h It can cost between USD 5,000 y USD 10,000, while a completely automatic line with production of 1 a 5 tons per hour It can overcome the USD 50,000.

In addition to the base price, factors such as the type of pasta (spaghetti, penne, flat noodles, etc.), The drying system, Automatic packaging and electrical requirements also influence the total cost.

And DT Food Machine OfRecemos Personalized solutions and professional advice to ensure that each client obtains the best equipment according to their budget and needs. Request a quote without obligation.