Introduction: What is a machine to make tomato puree and what is it for?

The tomato puree machine It is essential equipment in the food industry and in specialized kitchens., Designed to crush, Press and process fresh tomatoes, obtaining as a result a homogeneous puree ready for bottling, cook or conserve.

Tomato puree is the base of multiple products such as sauces., concentrates, pastas, soups and preserves. For this reason, have one efficient tomato processing machine improves performance, reduces waste and guarantees final product quality.

Types of Tomato Puree Making Machines

1. Domestic machine to prepare tomato puree

These machines are designed for home use, They are usually compact, manual or low power electric. They are used in small kitchens, family gardens and by gastronomic entrepreneurs.

Common characteristics:

- Ability: 10 a 20 kg/hour

- Materials: stainless steel or food plastic

- Easy disassembly and cleaning

- Engine of 200 a 500 W (yes it is electric)

Advantages:

- Economic

- Ideal for small quantities

- Portable and easy to use

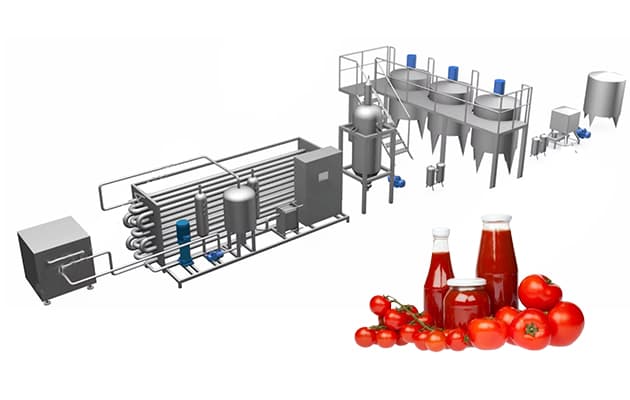

2. Industrial machine to make tomato puree

In the food industry, more robust and automatic machines are required. Is industrial machines for processing tomato They have high capacity, They operate continuously and are designed to withstand intensive work days..

Common uses:

- Sauces and preserves factories

- Food processing plants

- Agricultural cooperatives

Key features:

- Ability: from 300 kg/h up to more than 3 tons/h

- Food grade stainless steel construction

- Integration with peeling lines, scald, and bottled

- Variation of meshes or sieves for different textures

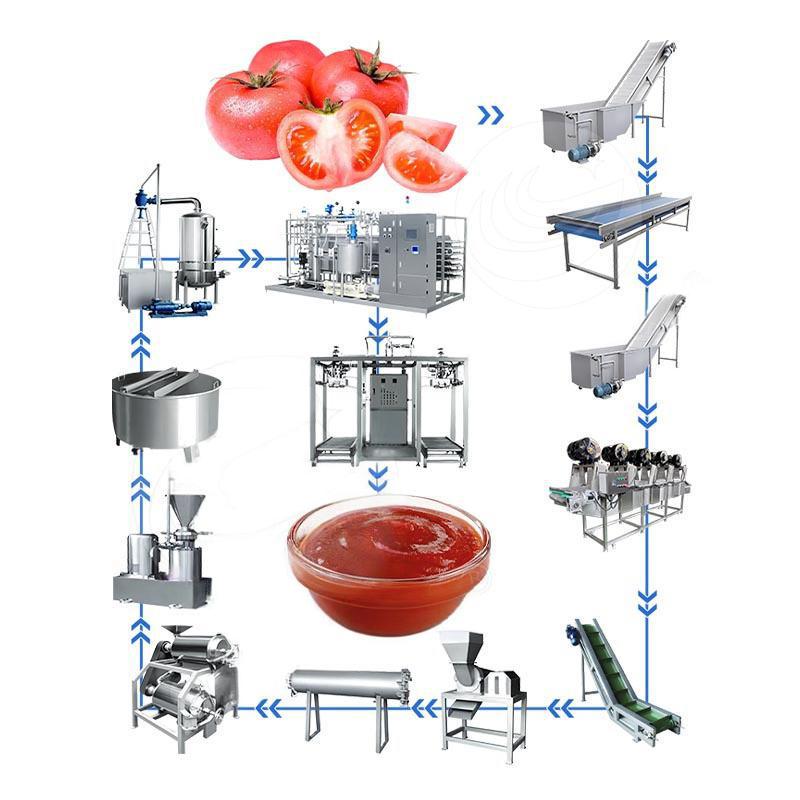

General Operation of a Tomato Puree Making Machine

The process may vary slightly between models, but generally follow the following steps:

- Washing and blanching the tomato (optional)

- Raw tomato feeding to the hopper

- Crushing and separation of skins and seeds

- Extraction of the puree through the lower outlet

- Collection in trays or direct integration with pasteurization or packaging line

Common Technical Parameters in Tomato Puree Machines

| Model | Ability (kg/h) | Power (kW) | Material | mesh size | Application |

|---|---|---|---|---|---|

| TM-100 | 100–150 | 0.75 | Stainless steel | 0.6 mm | Home/commercial use |

| TM-300 | 300–500 | 1.5 | SS304 | 0.8 mm | Restaurants, orchards |

| TM-1000 | 1000–1500 | 3.0 | SS316 | 1 mm | Small industries |

| TM-3000 PRO | 3000–5000 | 7.5 | SS316L | variable | Processing factories |

Main Parts of a Professional Tomato Puree Maker

1. Power hopper

It is the area where the whole tomatoes are placed. Can be made of stainless steel or resistant polyethylene.

2. crusher cylinder

Area in which tomatoes are pressed and crushed by rollers, blades or augers.

3. Separation mesh or sieve

Separate the juice and pulp from the seeds and skins. The fineness of the sieve determines the texture of the puree.

4. Engine and transmission

In electric or industrial models, the engine is essential. It varies between 0.5 y 10 kW depending on capacity.

5. Product output

It is where the processed puree is collected.. Can be connected to a tank, tray or automatic packaging system.

Advantages of Using an Industrial Tomato Puree Machine

- Time and labor savings

- Higher yield per kilogram of tomato

- More homogeneous purees free of impurities

- Adaptability to complete production lines

Maintenance and Cleaning of the Tomato Puree Maker

A well-maintained machine guarantees a longer useful life and food safety. Some tips:

- Clean with hot water and neutral soap after each use

- Disassemble moving parts to remove debris

- Check and lubricate mechanical components every week

- Avoid abrasive materials that scratch stainless steel

Integration with Other Tomato Processing Machines

On industrial lines, the tomato puree machine is complemented with:

- tomato washing machines

- Scalders

- Automatic peelers

- Pasteurizers

- Jar or bag filling and sealing machines

These machines can be connected by conveyor belts to achieve a fully automated tomato puree production line.

How to Choose the Right Tomato Puree Maker

Key factors to consider:

- Daily production volume

- Available space on the floor or kitchen

- Desired automation level

- Type of tomato to process (Roma, pera, cherry, etc.)

- Desired puree texture

Pro tip:

It is always advisable to request a test run before making the purchase., especially for industrial models.

Main Manufacturers of Tomato Puree Machines

- DT Food Machine Co., Ltd. (leader in complete tomato lines)

- Industrias Frutibérica S.L. (Space)

- Tecnoalimentaria Andina S.A.C. (Peru)

- Tomatequip S.R.L.. (Argentina)

These companies offer tailored solutions according to the type of client: from artisans to large agribusinesses.

Frequent questions (Rfq) about Tomato Puree Machines

1. Can the machine be used for other products besides tomatoes?

Yeah, many models allow you to crush other fruits such as mango, strawberry or papaya.

2. What preventive maintenance should be performed?

Daily cleaning, blade inspection and monthly bearing lubrication.

3. How much does an industrial tomato puree machine cost??

Prices vary between 1.000 y 20.000 USD according to capacity, brand and level of automation.

4. Does the machine automatically separate seeds and skin?

Yeah, professional models include sieves that retain impurities.

5. What certifications should the machine have??

It is recommended that it has CE certification, ISO 9001 and food grade materials.

Conclusion: Smart Investment for Entrepreneurship and Agri-Food Companies

Invest in one tomato puree machine appropriate to your production scale is a strategic decision. Whether to start an artisanal sauce business or modernize a canning factory, choosing the right equipment improves product quality, reduces costs and increases efficiency.

With a wide range of models, capacities and configurations available on the market, There is always a perfect machine for every need.