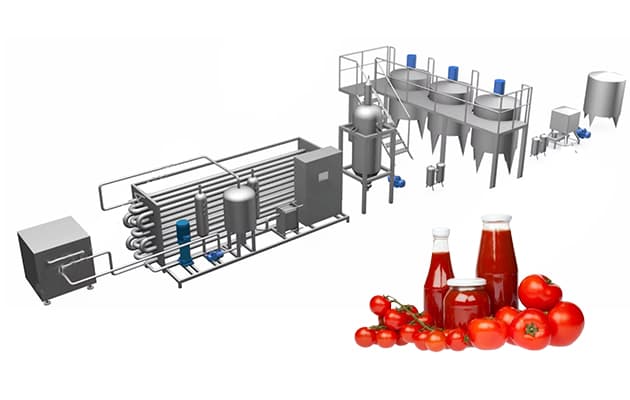

Tomato sauce machine

The tomato sauce machine is a equipment designed to optimize the entire tomato sauce manufacturing process, from the reception of tomato to its final packaging. Thanks to its automated design, It allows producers to obtain a high quality product more quickly and efficiency.

The process begins with the tomato washing machine, that eliminates any dirt or residue from the fruit, ensuring that only the cooler and more clean tomatoes are used. Then, The tomato passes through a crusher that makes it a homogeneous pulp, List for the next refining step.

Once the pulp is obtained, A refinement is used that eliminates seeds and skins, guaranteeing a soft and pleasant texture. Posteriorly, The pulp is concentrated in the concentrator, that reduces water content, achieving a thicker sauce with greater flavor.

Finally, The product will be packaged with the packaging, which ensures that tomato sauce is properly preserved and stays fresh until its consumption. This machine is ideal to improve productivity, reduce costs and offer a consistent and high quality product.

Tomato sauce machine

Industrial tomato washing machine

The washing machine is the first essential stage of any tomato sauce production line. This machine uses pressure water, upper and lower showers and rotating brushes to eliminate impurities such as earth, Plant leaves and remains.

The main objective is to ensure that tomatoes enter the process completely clean, avoiding cross contamination and ensuring a hygienic final product. Besides, Some models incorporate inspection tapes for additional visual control.

A good one Tomato sauce machine You must always start with an efficient washing machine, since initial cleaning directly affects the quality of the sauce.

Tomato crusher

After washing, The tomatoes are directed to the crusher. This machine converts whole tomatoes into a homogeneous pulp by stainless steel blades or rollers that crush the fruit with precision and speed.

Crushing allows you to separate the liquid part from the thickest fibers, facilitating the posterior refining. It also helps to free the natural juices of tomato without compromising the taste.

This stage is key in any Tomato sauce machine, since it prepares the base of the product evenly and continuously.

Tomato pulp preheater

The crushed pulp is transferred to the preheater, A machine that raises its temperature at approximately 65–75 ° C. This thermal process is essential to inactivate enzymes that can alter the taste and color of tomato.

Besides, Preheating reduces the bacterial load of the product before refining, improving food security. The consistency of puree also improves thanks to this heat treatment.

Within one Tomato sauce machine, The preheater contributes to prolong the useful life of the final product and conserve its freshness.

Tomato pulp refiner

The refiner is responsible for separating the skin, seeds and other unwanted solids of tomato puree. Use thin or centrifugal fine sieves to guarantee a soft and uniform texture.

Thanks to this process, A refined puree with excellent appearance and flavor is obtained. Besides, Improve the viscosity of the sauce, making it more pleasant to the palate and visually attractive.

A good refinement is indispensable in all Tomato sauce machine, since it transforms the product into a base ready to be cooked and seasoned.

Tomato sauce concentrator

The concentrator reduces the water content of puree by vacuum evaporation, without losing nutrients or altering the natural color of tomato. This allows to increase the content of soluble solids, achieving a densest texture.

The concentration process improves the stability and conservation of the sauce. Besides, facilitates the addition of ingredients without diluting the final product.

It is an essential part of the Tomato sauce machine, especially if you want to obtain products such as tomato paste or ketchup.

Mixer and tomato sauce cooker

At this stage the complementary ingredients such as salt are added, sugar, vinegar, garlic or spices. The mixer incorporates them homogeneously, While the cooker applies constant heat to enhance flavors.

Cooking reaches between 85 ° C and 95 ° C, ensuring adequate pasteurization. Acidity is also adjusted and the characteristic taste of salsa develops.

This part of the Tomato sauce machine defines the final profile of the product, both in taste and consistency.

Tomato sauce packaging machine

The final stage is packaging. The hot or sterilized sauce is introduced into bottles, vials, Sachets or cans through an automatic packaging, that also seals the containers tightly.

This process can include hot filling or in aseptic conditions, depending on the type of product. Some packagers also integrate labeling and lot coding.

The packaging is a key part of all Tomato sauce machine, since it protects product quality until its consumption.

Technical specifications and machine capacity to make tomato sauce

| Parameter | Basic model | Average model | Industrial model |

|---|---|---|---|

| Production capacity | 500 – 1,000 kg/h | 3,000 – 5,000 kg/h | 10,000 – 15,000 kg/h |

| Type of operation | Semi-automatic | Automatic | Automatic continues |

| Manufacturing material | Stainless steel 304 | Stainless steel 304/316 | 316L stainless steel |

| Energy consumption | 10 – 20 kW | 30 – 50 kW | 60 – 100 kW |

| Voltage required | 380V / 50Hz / 3 phases | 380V / 50Hz / 3 phases | 380V / 50Hz / 3 phases |

| Tomato washing machine | 1000 kg/h | 4000 kg/h | 10,000+ kg/h |

| Crusher | 1000 kg/h | 5000 kg/h | 15,000 kg/h |

| Refinery | 800 kg/h | 4000 kg/h | 12,000 kg/h |

| Concentrator (empty) | 1 stage, 500 L/h | 2 stages, 2000 L/h | 3 stages, 5000+ L/h |

| Cook/mixer | 200 – 500 L/h | 1000 – 3000 L/h | 5000 – 8000 L/h |

| Control system | Basic Panel with buttons | PLC with touch screen | Advanced PLC with Tactile HMI |

| Cleaning system (CIP) | Manual | Semiautomatic | Complete automatic |

| It requires operators | 2 – 3 personas | 3 – 5 personas | 6 – 8 personas |

| Required area (approx.) | 30 – 50 m² | 80 – 120 m² | 200 – 400 m² |

All our machines comply with international quality and safety regulations, guaranteeing efficient and safe functioning.

Rfq- Tomato sauce machine

1. What is the production capacity available?

We offer models from 500 kg/h to 15 tons per hour. We can customize according to your daily processing volume.

2. What components includes the full line?

The standard line includes: washing machine, crusher, preheater, refinery, concentrator, Mixer-scout, Filling system and conveyor belt. Can also be adapted.

3. Can it be used with other products in addition to tomato?

Yeah. Can be adapted for peppers, Fruits like mango the cutter, and other sauces or purés.

4. Is it made of food stainless steel?

Yeah. The entire machine is made of stainless steel 304 o 316, complying with international food standards.

5. How much space do I need to install the line?

From 30 m² for small models up to 400 m² for industrial lines. We offer design plans according to your plant.

6. How many operators does the line need?

Small models require 2-3 personas, medium 4-5, and industrial lines until 8 operary.

7. Can you install the machine in my country?

Yeah. We offer on situ installation, Technical training, and international post -sales support.

8. What is the delivery period?

Usually of 25 a 60 working days, Depending on the model and the required customization.

9. What guarantee do you offer?

We offer 12 months of guarantee for main pieces, With technical service available by video call or visit.

10. What type of packaging and transportation use?

The machine is packed in wooden boxes treated for export. Shipping can be by sea, AIRE LAND TRANSPORT, According to your needs.

Machine manufacturers for tomato sauce

In DT Food Machine we are leading manufacturers of Tomato sauce machines, With more than 15 Years of experience in complete solutions for tomato processing. From production lines 500 kg/h to industrial plants of 15 tons per hour, We offer equipment designed to satisfy both artisanal producers and large -scale factories.

What differentiates us is our approach to the quality, Post -sales automation and service. Our machines are manufactured in stainless steel (304/316), complying with international hygiene and safety regulations. Besides, We incorporate advanced technology as PLC controls, Vacuum CIP and evaporators who ensure greater performance and energy efficiency.

We offer key key solutions that include layout design, Installation at destination, Technical training and rapid spare parts. We export to more than 30 countries in Latin America, Africa and Asia, which demonstrates our ability to adapt to different markets and requirements.

If you are looking for a reliable partner to mount your tomato sauce plant, DT Food Machine is his best choice. We deliver more than machinery: We deliver productivity, Durable quality and technical support.

Cocoa Processing Production Price Price

The price of a tomato sauce machine varies according to production capacity, the level of automation and the components included. For small lines (500 kg/h), The price can start from USD 8,000 a 15,000. In medium models (3-5 tons/hour), The range goes up to USD 100,000 – 400,000, while for industrial lines (10-15 tons/hour) can overcome the USD 1,000,000.

In addition to the size, factors such as material (stainless steel 304 o 316), The brand of electrical components, And if it includes systems such as vacuum evaporator or automatic CIP they also directly influence the final price.

For an exact contribution, Contact us with your production and space requirements available.