Yogurt machine

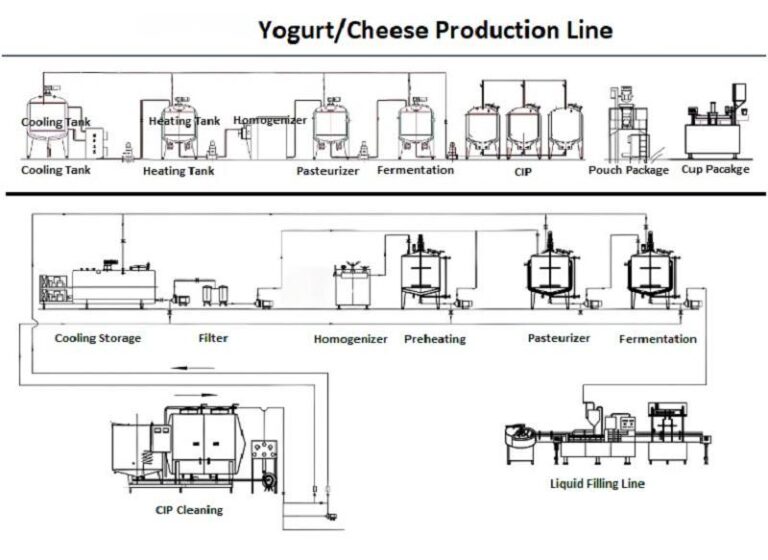

The Yogurt machine It is a reliable and efficient solution to produce high quality yogurt. Made of Food Degree Stainless Steel, Combine durability with strict hygiene standards, guaranteeing safe and lasting performance in any dairy processing environment.

With an advanced temperature regulation system and automatic mixing, The machine allows precise control of the fermentation process. This ensures a soft texture, an intense flavor and uniform quality in each lot, Whether natural yogurt or flavors occur. Its flexibility makes it ideal for both small businesses and large -scale factories.

The ease of use is another advantage of the Yogurt machine. Just configure the desired parameters, The system works automatically, minimizing manual work and reducing production costs, At the same time that it maintains results of excellence.

This machine is the perfect choice for dairy companies that seek to improve efficiency, Expand its capacity and offer the market premium yogurt products with ease and consistency.

Yogurt machine

Storage tanks

Los milk storage tanks They are essential to maintain freshness and product quality from milking until processing. They are designed to conserve milk in hygienic and safe conditions.

Made of Food Degree Stainless Steel, They have cooling systems that allow maintaining the appropriate temperature, avoiding the growth of bacteria and preserving nutritional properties.

These tanks are found in different capacities and models, adapting to dairy farms and processing plants. Thanks to its technology, They guarantee efficiency, Durability and compliance with the standards of the dairy industry.

Duplex filter

He duplex filter It is a equipment designed for continuous filtration of liquids in industrial processes. Its main advantage is to allow the change from one filter element to another without stopping the workflow.

Manufactured in corrosion -resistant materials, offers high efficiency in the elimination of impurities and solid particles. This guarantees greater protection of bombs, production pipes and equipment.

Its compact and versatile design makes it ideal for the food industry, Chemistry and pharmaceutical. The duplex filter ensures continuity, quality and reliability in each filtration process.

Homogenizing

He homogenizing It is a equipment used in the food industry, dairy and pharmaceutical to obtain uniform and stable mixtures. Its main function is to reduce the size of the particles and disperse them homogeneously in the liquid.

Thanks to its high pressure technology, Improves texture, The taste and life of products such as milk, juices, sauces and creams. Besides, guarantees better absorption and stability in emulsions and suspensions.

Manufactured in stainless steel, Homogeneizer offers resistance, easy cleaning and compliance with hygienic standards. It is a key tool to ensure quality and consistency in productive processes.

Yogurt fermentation tank

He Yogurt fermentation tank It is a team specialized in the process of making fermented dairy products. Its design allows optimal temperature and time conditions necessary to cultivate lactic bacteria.

Manufactured in stainless food grade, guarantees hygiene, Resistance and ease of cleanliness. Besides, You can incorporate automatic agitation and control systems to ensure uniform fermentation.

This type of tank is essential in dairy plants, since it ensures quality, The taste and texture of yogurt, Fulfilling food safety standards.

Filling and covered machine

The Filling and covered machine It is a fundamental equipment in beverage production lines, dairy, oils and liquid products in general. Its function is accurately dose the container content and seal them safely.

These machines are made of stainless steel, what ensures hygiene, Durability and easy maintenance. They can work with different types of containers and caps, adapting to the needs of each industry.

Thanks to its high efficiency and automation, The filling and cover machine optimizes the production process, reduces costs and guarantees the final quality of the product in the market.

Cleaning in the place

He Cleaning system in the place (CIP, by its acronym in English) It allows hygienizing equipment and pipes without disarming them. It is essential in food industries, dairy and pharmaceutical to maintain high cleaning standards.

CIP uses chemical solutions, temperature and controlled pressure to remove waste, bacteria and pollutants, guaranteeing the safety of the final product. Its automation reduces errors and saves time in cleaning processes.

Implement cleaning in place ensures efficiency, Water and energy savings, In addition to complying with health regulations. It is a key tool to maintain quality and safety in production.

Technical specifications and machine capacity to make yogurt

| Production (L/h) | Model | Number of tanks | Tank material | Heating system | Refrigeration system |

|---|---|---|---|---|---|

| 100 | The-100 | 1 | Stainless steel 304 | Electric / Vapor | Direct / Serpentine |

| 200 | The -200 | 1–2 | Stainless steel 304 | Electric / Vapor | Direct / Serpentine |

| 500 | The 500 | 2 | Stainless steel 304 | Electric / Vapor | Direct / Serpentine |

| 1000 | That-1000 | 2–4 | Stainless steel 304 | Electric / Vapor | Direct / Serpentine |

| 2000 | That-2000 | 4 | Stainless steel 304 | Electric / Vapor | Direct / Serpentine |

| Temperature control | Time control | Agitation system | Dimensions (L×W×H, mm) | Weight (kg) | Power supply |

|---|---|---|---|---|---|

| Digital 30–45°C | 0–24 h | Adjustable automatic | 1200×800×1500 | 180 | 220V / 50Hz |

| Digital 30–45°C | 0–24 h | Adjustable automatic | 1500×1000×1600 | 250 | 380V / 50Hz |

| Digital 30–45°C | 0–24 h | Adjustable automatic | 2000×1200×1800 | 400 | 380V / 50Hz |

| Digital 30–45°C | 0–24 h | Adjustable automatic | 2500×1500×2000 | 700 | 380V / 50Hz |

| Digital 30–45°C | 0–24 h | Adjustable automatic | 3500×1800×2200 | 1200 | 380V / 50Hz |

All our machines comply with international quality and safety regulations, guaranteeing efficient and safe functioning.

Rfq- Yogurt machine

1. What is the production capacity of the machine?

Answer: Depending on the model, The machine can produce between 100 y 2000 Liters of yogurt per hour, adapting to small, medium and large plants.

2. What materials are used in machine tanks?

Answer: All tanks are made of stainless steel 304 of food degree, corrosion resistant and easy to clean.

3. What heating and cooling systems does the machine have?

Answer: You can use electric or steam heating, and direct or serpentine cooling systems according to the model.

4. Are the temperature and fermentation time controllable?

Answer: Yeah, The machine includes digital temperature control (30–45°C) and 0–24 hours programmable timer to ensure precise fermentation.

5. What kind of agitation use the machine?

Answer: Automatic and adjustable agitation system that guarantees uniformity in the mixture and constant quality of yogurt.

6. What packaging sizes can the machine handle?

Answer: The machine can be adapted to different packaging sizes through accessories and adjustments, ideal for bulk production or individual packaging.

7. What is the electrical consumption of the machine?

Answer: Small models use 220v/50Hz, while industrial models use 380v/50Hz, With efficient consumption according to capacity.

8. Does the machine meet food hygiene standards?

Answer: Yeah, complies with FDA and CE standards, guaranteeing safety and hygiene in yogurt production.

9. Is installation and training included when buying the machine?

Answer: Yeah, We offer installation, Complete and training staff for optimal operation.

10. What is the delivery time and guarantee of the equipment?

Answer: Delivery time is usually 30 a 60 days according to the model. The standard guarantee is 12 months, With technical support available subsequently.

Machine manufacturers for yogurt

Los Machine manufacturers for yogurt face the challenge of offering equipment that combines efficiency, SAFETY AND QUALITY IN EACH PRODUCTION LOT. Our company is distinguished by being a reference in the industry, providing Yogurt machines designed to meet the demands of small producers and large factories equally. Each machine is made of food grade stainless steel, guaranteeing durability, hygiene and optimal performance at all times.

Why choose us?

First of all, We offer complete solutions that include technical advice, Installation and post -sales support, ensuring that each client obtains the maximum performance of their investment. Besides, Our machines have intelligent temperature control systems and automatic mixing, which allows a precise and consistent fermentation process, achieving a soft texture and uniform taste.

Our experience as Machine manufacturers for yogurt It allows us to customize equipment according to the specific needs of each business, From handmade production to large -capacity industrial lines. We are committed to innovation and continuous improvement, incorporating advanced technology that optimizes performance and reduces operating costs.

Machine price to make yogurt

He Price of a yogurt machine varies according to the capacity and level of automation, From small models for handmade producers to industrial equipment from 500 a 2000 liters per hour. In DT Food Machine, We offer competitive prices and solutions adapted to each need, guaranteeing high quality machinery made of stainless steel 304.

Besides, We provide full technical support, including installation, Personnel starting and training. Our temperature control systems, Automatic timer and agitation ensure uniform and efficient production.

When choosing DT Food Machine, Customers get not only a reliable team, but also continuous professional assistance, guaranteeing that the investment is profitable and safe from the first day.