Demand for peanut butter has grown rapidly in Latin American markets, USA, Europe and Africa. Both small entrepreneurs and consolidated factories are looking for a peanut butter machine make it efficient, segura, hygienic and capable of producing high quality peanut butter. Due to this increase in consumption, More and more entrepreneurs are looking to invest in a peanut butter production line, that goes from the peeling of the peanut to the final packaging.

You will find a complete guide, clear and totally practical on how to choose a peanut butter maker, how the process works, what are its components, the capacity you need for your business, The operating costs and benefits of investing in industrial equipment.

1. What is a Peanut Butter Machine?

A peanut butter machine It is an industrial equipment designed to crush, grind and refine roasted peanuts into a smooth paste, homogeneous and fine texture. In the industry it is also known as:

- Peanut butter

- colloidal mill for peanuts

- Industrial equipment for peanut butter

- Peanut Butter Making Machine

- peanut butter processing machine

- peanut butter machine

Depending on the type of production, These machines can work independently or be part of a complete peanut butter production line, which includes toaster, peeler, Colloidal mill, mixing tank, cooling system, sanitary pump, storage tank and packaging machine.

2. How Does a Peanut Butter Maker Work??

The operating principle is based on the colloidal grinding: roasted peanut is fed to the mill, where a set of rotating and fixed discs reduces particles through shear force, impact and friction.

The complete process includes:

2.1. Feeding and dosage

Roasted peanuts enter the mill through a hopper. Controlled dosage allows for uniform grinding.

2.2. High speed grinding

Inside the colloidal mill, The discs rotate at speeds between 2.800 y 3.600 rpm.

This allows you to obtain a texture:

- Suave

- Creamy

- No lumps

- No hard particles

It is also possible to adjust the level of fineness according to customer needs.

2.3. Recirculation and refining

Many equipment allows the product to be recirculated until the desired texture is reached.. Particles smaller than 70–100 microns can be obtained., which is the professional standard for premium peanut butter.

2.4. Discharge and pumping

The final paste is discharged continuously and can be sent to:

- a mixing tank,

- a cooling system,

- or an automatic packaging machine.

3. Main Components of an Industrial Peanut Butter Machine

A complete production line may include:

3.1. Peanut roaster

Roast peanuts at a precise temperature to improve flavor, eliminate moisture and facilitate grinding.

3.2. peeling machine

Removes the peanut skin quickly without affecting the integrity of the kernel.

3.3. Colloidal mill

The heart of the system.

It is the equipment in charge of turning peanuts into cream..

3.4. Mixer or mixing tank

Allows you to add ingredients such as:

- sal

- sugar

- Honey

- vegetable oil

- flavorings

- natural stabilizers

3.5. Cooling system

To avoid the separation of the natural oil of the peanut, the product must be cooled while mixing.

3.6. storage tank

Keeps peanut butter sanitary before packaging.

3.7. packaging machine

Fill glass containers, plastic, doypack or bottles.

4. Advantages of Investing in a Peanut Butter Machine

Buy one industrial peanut butter machine offers multiple benefits:

4.1. High profitability

Peanuts are economical and peanut butter has high added value.

4.2. Continuous production

Industrial equipment can work 24/7 without interruptions.

4.3. Different levels of capacity

There are teams from 50 kg/h to 2 tons per hour.

4.4. Various final products

With the same line you can produce:

- natural peanut butter

- extra smooth peanut butter

- chunky peanut butter

- sweetened peanut butter

- organic peanut butter

- seed paste (almond, sesame, pistachio, anacard)

4.5. Hygiene and food safety

Generally made of food grade stainless steel.

5. What Capacity Do I Need for My Business?

It will depend on the type of market:

small production (50–150 kg/h)

Ideal for:

- entrepreneurship,

- small local brands,

- professional craft production.

Medium production (150–500 kg/h)

Suitable for:

- distributors,

- regional brands,

- food laboratories.

Large production (500–2000 kg/h)

Addressed to:

- exporting factories,

- food processors,

- consolidated brands.

6. How to Choose the Best Peanut Butter Maker?

6.1. Construction material

The best option is stainless steel 304 o 316.

6.2. Grinding system

Choose a high speed colloid mill, with hardened or stainless steel discs.

6.3. fineness adjustment

Good equipment should allow you to adjust the texture of the final product.

6.4. Cleaning and maintenance

Look for equipment with sanitary design and easy disassembly.

6.5. Technical and Spare Service

An essential aspect in an industrial production line.

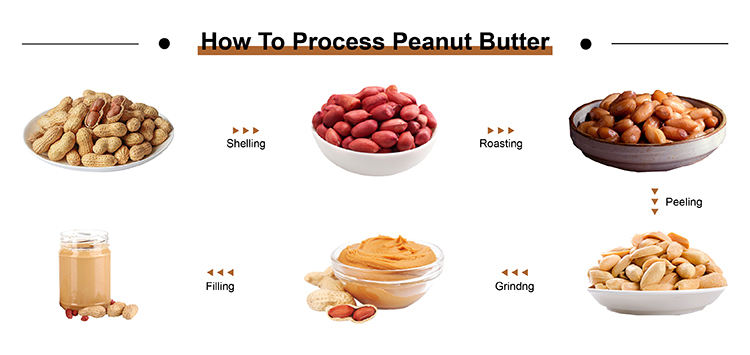

7. Complete Peanut Butter Manufacturing Process (Step by step)

- Peanut selection

- Washing and drying

- Uniform toast

- Cooled to avoid condensation

- Peeled

- Primary grinding

- Fine grinding and refining

- Mixed with ingredients

- Cooling and stabilization

- Packaging and labeling

Each step influences the flavor, texture, color and shelf life of the final product.

8. Commercial Applications of a Peanut Butter Machine

With the same equipment you can produce:

- Nut cream

- almond cream

- Tahini

- pistachio paste

- sesame paste

- cashew butter

- Hazel paste

This turns investment into a business multi-product and more profitable.

9. How Much Does a Peanut Butter Machine Cost??

The price depends on:

- ability,

- material,

- automation,

- additional accessories,

- country of destination.

On average:

- 50–100 kg/h → economic

- 150–300 kg/h → gamma media

- 500 kg/h - 2 ton/h → complete industrial lines

If you want, I can help you prepare one full quote, with technical table and plant design.

10. peanut butter machine

The peanut butter machine It is one of the most stable and profitable investments in the food sector. Peanut butter consumption continues to increase globally, and current equipment makes it possible to produce healthy versions, organic and premium, adapted to the demands of the modern market.

Whether you want to start a small project or install a large peanut butter production line, Choosing the right equipment will determine the quality of the final product and the efficiency of your factory.