Introduction

A cocoa production line is essential to transform cocoa beans into ready-to-eat products.. Cocoa is the fundamental raw material for the manufacture of chocolate and various derived products. To achieve efficient and automated production, It is crucial to have a well -designed system. In this article, We will explore in detail what a cocoa production line is, the processes involved and the benefits of their automation.

What is a cocoa production line?

A cocoa production line is a set of processes and equipment designed to transform cocoa beans into finished products such as cocoa paste., cocoa butter and cocoa powder. This line can be manual, semi-automated or fully automated, depending on the level of technology implemented.

Types of cocoa production lines

There are several types of cocoa production lines, each designed according to the production scale and the specific needs of the manufacturers:

- Artisanal line: Ideal for small producers and artisanal chocolatiers.

- Semi-industrial line: Combine manual processes with automated equipment.

- Automated industrial line: Used by large manufacturers to maximize production and efficiency.

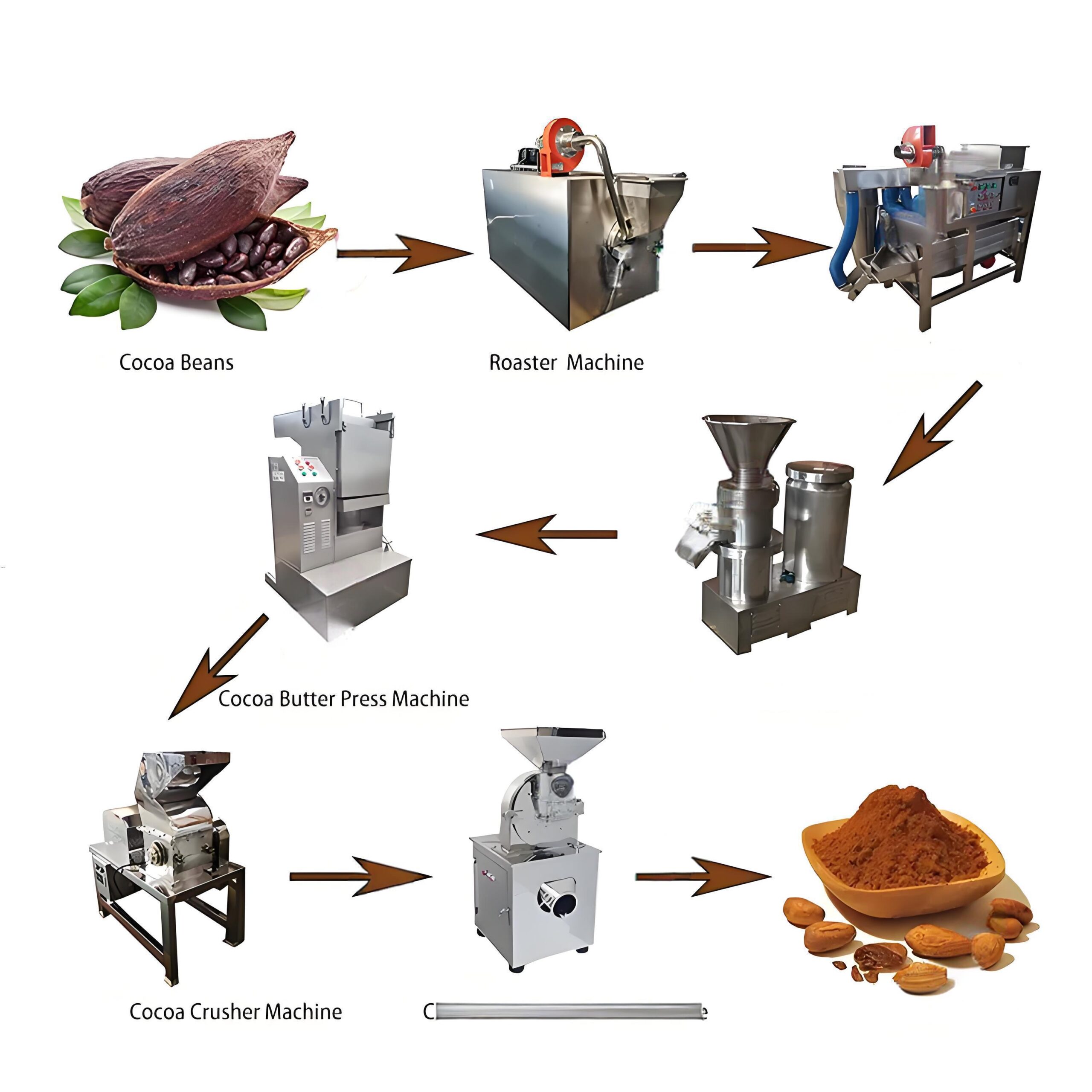

Cocoa production process: step by step

Grain selection and cleaning

The first step is the selection and cleaning of the cocoa beans to eliminate impurities such as stones., branches or dust. This guarantees high quality raw materials.

Fermentation and drying

Cocoa beans undergo a fermentation process that lasts between 5 y 7 days, which allows the precursors of chocolate flavor to develop. Then, They are dried in the sun or using industrial dryers.

Roasted and hulled

Roasting enhances the flavors of the cocoa and makes it easier to separate the shell., which is removed in the hulling process to obtain cocoa nibs.

Grinding and refined

Cocoa nibs are ground into a cocoa paste., which is then refined to achieve a smoother and more homogeneous texture.

Pressing and manufacturing of derived products

Cocoa paste is pressed to separate the cocoa butter from the cocoa powder, that will be used in the production of chocolate and other products.

Benefits of an automated production line

- Greater efficiency and productivity

- Reduction of production costs

- Consistent quality in final products

- Less raw material loss

Essential equipment in a cocoa production line

- Cleaning and classification: Impurity separators and grain classifiers.

- Fermentation and drying: Fermentation trays and solar or mechanical dryers.

- Toasted: Temperature controlled roasting ovens.

- Grinding and refined: Roller mills and ball refiners.

- Pressing: Hydraulic presses for cocoa butter extraction.

Key factors to optimize cocoa production

- Raw material quality: Selection of high quality grains.

- Temperature and humidity control: Key factors in fermentation and drying.

- Equipment maintenance: Reduction of failures and increased efficiency.

Conclusion

A well-designed cocoa production line is key to obtaining high-quality products and optimizing the performance of the raw material.. With the use of advanced technology and the implementation of good practices, it is possible to improve efficiency and reduce costs in the manufacture of cocoa derivatives.