The Linia do produkcji makaronu instant is a highly automated food processing system designed for the continuous manufacture of fried and non-fried instant noodles. Ten typ sprzętu integruje mieszanie mąki, folia ciasta, parowanie, cięcie, smażenie lub suszenie, i pakowanie w ramach usprawnionego przepływu pracy.

Dla fabryk żywności, inwestorzy komercyjni, i producentów makaronów błyskawicznych, understanding the detailed technical parameters of each unit is essential when selecting a production line that meets specific capacity, energy, and quality requirements.

Instant Noodle Production Line Equipment Overview

The automatic instant noodle production system generally includes:

- Flour mixing machine

- Dough sheeting and compounding rollers

- Continuous rolling and thickness control

- Noodle slitter and wave forming machine

- Steaming chamber

- Cutting and folding device

- Frying or drying unit

- Cooling conveyor

- Seasoning unit (optional)

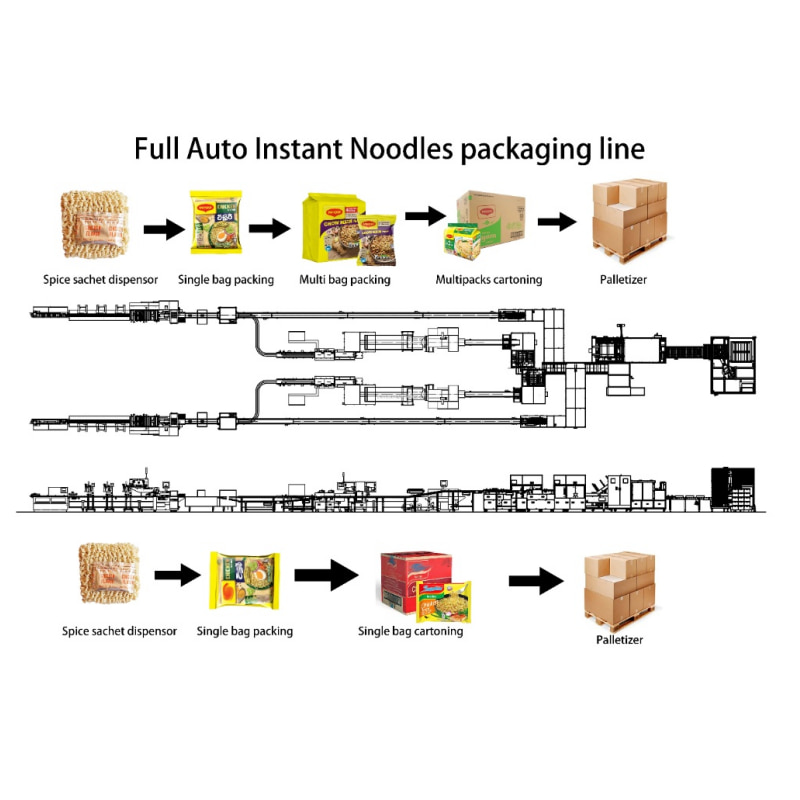

- Packaging machine

Technical Parameters of Instant Noodle Production Line Machinery

Flour Mixing Machine for Instant Noodle Production Line

- Funkcjonować: Mixes flour with water and additives into a uniform dough.

- Technical Specifications:

| Parameter | Range/Specification |

|---|---|

| Mixing capacity | 50 - - 300 kg/batch |

| Mixing time | 10 - - 15 minutes |

| Power consumption | 4 - - 11 kW |

| Water addition ratio | 28 - - 32% |

| Construction material | SUS304 stainless steel |

Dough Sheeting Section in Instant Noodle Production Line

- Funkcjonować: Compresses dough into sheets and strengthens gluten.

- Technical Specifications:

| Parameter | Range/Specification |

|---|---|

| Roller width | 300 - - 800 mm |

| Sheet thickness | 0.8 - - 2.0 mm |

| Pressure range | Up to 30 tons |

| Conveyor speed | 5 - - 15 m/min |

| Tworzywo | Food-grade stainless steel rollers |

Rolling and Compounding in Instant Noodle Manufacturing Line

- Funkcjonować: Reduces dough thickness step by step to achieve desired noodle texture.

- Technical Specifications:

| Parameter | Range/Specification |

|---|---|

| Rolling stages | 5 - - 7 |

| Final sheet thickness | 0.8 - - 1.2 mm |

| Speed adjustment | Frequency inverter controlled |

| Roller finish | Chrome-plated, corrosion resistant |

Noodle Slitter in Automatic Instant Noodle Line

- Funkcjonować: Cuts dough sheets into noodle strands and shapes them into wavy or straight noodles.

- Technical Specifications:

| Parameter | Range/Specification |

|---|---|

| Slitting speed | 50 - - 150 cuts/min |

| Noodle width options | 0.8 - - 1.5 mm |

| Wave pitch adjustment | Variable mechanical setting |

| Noodle length control | 300 - - 500 mm |

Steaming Section of Industrial Instant Noodle Line

- Funkcjonować: Gelatinizes starch and sets noodle structure.

- Technical Specifications:

| Parameter | Range/Specification |

|---|---|

| Steam temperature | 100 - - 105 °C |

| Steaming duration | 1 - - 3 minutes |

| Steam pressure | 0.15 - - 0.2 MPa |

| Steam consumption | 200 - - 400 kg/h |

| Chamber length | 5 - - 10 M |

Cutting and Folding Unit in Instant Noodle Production Line

- Funkcjonować: Cuts noodles into blocks and folds them into required mold shapes.

- Technical Specifications:

| Parameter | Range/Specification |

|---|---|

| Block size | 65 - - 85 mm |

| Block weight | 60 - - 100 G |

| Cutting accuracy | ±1.5 mm |

| Folding type | Single or double fold |

Frying Machine in Instant Noodle Production Plant

- Funkcjonować: Removes moisture from noodles while enhancing taste and shelf life.

- Technical Specifications:

| Parameter | Range/Specification |

|---|---|

| Oil temperature | 150 - - 160 °C |

| Frying duration | 90 - - 120 seconds |

| Oil consumption | 600 - - 1200 kg/day |

| Fryer length | 5 - - 8 M |

| Heating method | Gaz, diesel, or electric |

Drying System in Non-Fried Instant Noodle Production Line

- Funkcjonować: Dehydrates noodles using hot air drying instead of frying.

- Technical Specifications:

| Parameter | Range/Specification |

|---|---|

| Drying temperature | 60 - - 80 °C |

| Drying duration | 30 - - 60 minutes |

| Final moisture content | ≤ 12% |

| Dryer type | Continuous hot air tunnel |

| Pojemność | 100 - - 200 packs/min |

Cooling Conveyor in Instant Noodle Production Equipment

- Funkcjonować: Stabilizes temperature before packaging.

- Technical Specifications:

| Parameter | Range/Specification |

|---|---|

| Cooling time | 5 - - 10 minutes |

| Conveyor length | 4 - - 8 M |

| Cooling system | Forced air circulation |

Packaging Machine for Instant Noodle Production Line

- Funkcjonować: Packs noodles into sealed bags.

- Technical Specifications:

| Parameter | Range/Specification |

|---|---|

| Packaging speed | 80 - - 120 packs/min |

| Bag dimensions | 70 × 100 mm – 120 × 150 mm |

| Film type | BOPP, ZWIERZAK DOMOWY, laminated |

| Sealing method | Heat sealing |

| Control system | PLC touchscreen |

Instant Noodle Production Line Capacity Reference

| Model | Pojemność (packs/8h) | Moc (kW) | Floor Space (m²) |

|---|---|---|---|

| Small Instant Noodle Line | 50,000 - - 80,000 | 80 - - 100 | 150 - - 200 |

| Medium Instant Noodle Line | 120,000 - - 200,000 | 120 - - 160 | 250 - - 400 |

| Large Instant Noodle Line | 250,000 - - 350,000 | 200 - - 250 | 450 - - 600 |

| Extra Large Production Line | 400,000+ | 280 - - 350 | 700 - - 900 |

Automation and Energy Use in Instant Noodle Production Line

- PLC control systems with touchscreen HMI.

- Variable frequency drives for roller and conveyor adjustment.

- Oil filtration and recycling systems.

- Energy consumption:

- Para: 200 - - 400 kg/h

- Electricity: 120 - - 350 kW

- Olej (fried line): 8 - - 12% of noodle weight

Standards for Instant Noodle Production Line

- CE Certification – for European markets

- ISO 9001:2015 – Quality management system

- HACCP compliance – Food safety assurance

- FDA food-grade materials – For North America

RFQ – Instant Noodle Production Line Frequently Asked Questions

Q1: What is the production capacity of your instant noodle production line?

A1: We offer production lines ranging from 50,000 packs to over 400,000 packs per 8 godziny. Small, średni, and large-scale lines can be customized based on your market demand.

Q2: Can your instant noodle production line produce both fried and non-fried noodles?

A2: Tak. We provide fried instant noodle lines with continuous fryers and non-fried instant noodle lines with hot air dryers. Both types can be customized according to your recipe requirements.

Q3: What is the typical block size and weight of instant noodles produced?

A3: Standard noodle block size is 65–85 mm in length with weights from 60–100 g. These parameters can be adjusted according to your target market.

Q4: What raw materials are required for production?

A4: The main raw material is wheat flour. Additional ingredients include woda, sól, alkaline agents, and optional seasonings. Our line supports both standard recipes and customized formulations.

Q5: How much power and steam does the instant noodle production line consume?

A5: Depending on the capacity:

- Electricity: 120 - - 350 kW

- Para: 200 - - 400 kg/h

- Oil consumption (do smażonego makaronu): 8 - - 12% of noodle weight

Q6: What certifications do your machines have?

A6: Our equipment complies with CE certification, ISO 9001:2015, HACCP standards, and FDA food-grade material requirements for international markets.

Q7: What is the delivery time for an instant noodle production line?

A7: The standard delivery time is 60–90 dni depending on customization level, line size, and order quantity.

Q8: Do you provide installation and training services?

A8: Tak. We offer on-site installation guidance, operator training, and technical documentation. Remote technical support is also available.

Q9: Can the packaging machine handle different bag sizes?

A9: Tak. Our packaging unit supports 70 × 100 mm up to 120 × 150 mm bag sizes. It is compatible with BOPP, ZWIERZAK DOMOWY, and laminated films with heat sealing.

Q10: What after-sales services are available?

A10: We provide one-year warranty, lifelong spare parts supply, remote troubleshooting, and optional on-site maintenance services worldwide.

Choosing an Instant Noodle Production Line Manufacturer

The instant noodle production line offers food factories a reliable and efficient system for large-scale production. By examining the technical specifications—mixing capacity, roller width, steaming performance, fryer size, and packaging speed—buyers can choose the right model for their requirements.

Whether small, średni, or large scale, a well-selected instant noodle line guarantees stable product quality, energy efficiency, i zgodność z międzynarodowymi standardami bezpieczeństwa żywności.