O Linha de produção instantânea de macarrão é um sistema de processamento de alimentos altamente automatizado projetado para a fabricação contínua de macarrão instantâneo frito e não frito. Este tipo de equipamento integra a mistura de farinha, Folha de massa, cozinhando a vapor, corte, fritar ou secar, e embalagem em um fluxo de trabalho simplificado.

Para fábricas de alimentos, investidores comerciais, e fabricantes instantâneos de macarrão, compreender os parâmetros técnicos detalhados de cada unidade é essencial ao selecionar uma linha de produção que atenda à capacidade específica, energia, e requisitos de qualidade.

Visão geral do equipamento da linha de produção de macarrão instantâneo

O sistema automático de produção de macarrão instantâneo geralmente inclui:

- Máquina misturadora de farinha

- Folhas de massa e rolos de composição

- Laminação contínua e controle de espessura

- Máquina cortadora de macarrão e formadora de ondas

- Câmara de vapor

- Dispositivo para cortar e dobrar

- Unidade de fritura ou secagem

- Transportador de resfriamento

- Unidade de tempero (opcional)

- Máquina de embalagem

Parâmetros técnicos de máquinas para linha de produção de macarrão instantâneo

Máquina de mistura de farinha para linha de produção de macarrão instantâneo

- Função: Mistura farinha com água e aditivos até formar uma massa uniforme.

- Especificações Técnicas:

| Parâmetro | Faixa/Especificação |

|---|---|

| Capacidade de mistura | 50 - 300 kg/lote |

| Tempo de mistura | 10 - 15 minutos |

| Consumo de energia | 4 - 11 KW |

| Proporção de adição de água | 28 - 32% |

| Material de construção | Aço inoxidável SUS304 |

Seção de cobertura de massa na linha de produção de macarrão instantâneo

- Função: Comprime a massa em folhas e fortalece o glúten.

- Especificações Técnicas:

| Parâmetro | Faixa/Especificação |

|---|---|

| Largura do rolo | 300 - 800 milímetros |

| Espessura da folha | 0.8 - 2.0 milímetros |

| Faixa de pressão | Até 30 toneladas |

| Velocidade do transportador | 5 - 15 m/meu |

| Material | Rolos de aço inoxidável de qualidade alimentar |

Laminação e composição na linha de fabricação de macarrão instantâneo

- Função: Reduz a espessura da massa passo a passo para obter a textura desejada do macarrão.

- Especificações Técnicas:

| Parâmetro | Faixa/Especificação |

|---|---|

| Estágios rolantes | 5 - 7 |

| Espessura final da folha | 0.8 - 1.2 milímetros |

| Ajuste de velocidade | Inversor de frequência controlado |

| Acabamento em rolo | Cromado, resistente à corrosão |

Cortador de macarrão em linha automática de macarrão instantâneo

- Função: Corta folhas de massa em fios de macarrão e molda-os em macarrão ondulado ou reto.

- Especificações Técnicas:

| Parâmetro | Faixa/Especificação |

|---|---|

| Velocidade de corte | 50 - 150 cortes/min |

| Opções de largura de macarrão | 0.8 - 1.5 milímetros |

| Ajuste de pitch de onda | Configuração mecânica variável |

| Controle de comprimento do macarrão | 300 - 500 milímetros |

Seção de vapor da linha industrial de macarrão instantâneo

- Função: Gelatiniza o amido e define a estrutura do macarrão.

- Especificações Técnicas:

| Parâmetro | Faixa/Especificação |

|---|---|

| Temperatura do vapor | 100 - 105 °C |

| Duração do vapor | 1 - 3 minutos |

| Pressão de vapor | 0.15 - 0.2 MPa |

| Consumo de vapor | 200 - 400 kg/h |

| Comprimento da câmara | 5 - 10 eu |

Unidade de corte e dobra na linha de produção de macarrão instantâneo

- Função: Corta macarrão em blocos e dobra-os nos formatos necessários.

- Especificações Técnicas:

| Parâmetro | Faixa/Especificação |

|---|---|

| Tamanho do bloco | 65 - 85 milímetros |

| Peso do bloco | 60 - 100 g |

| Precisão de corte | ±1,5 mm |

| Tipo dobrável | Dobra simples ou dupla |

Máquina de fritar em planta de produção de macarrão instantâneo

- Função: Remove a umidade do macarrão enquanto melhora o sabor e a vida útil.

- Especificações Técnicas:

| Parâmetro | Faixa/Especificação |

|---|---|

| Temperatura do óleo | 150 - 160 °C |

| Duração da fritura | 90 - 120 segundos |

| Consumo de óleo | 600 - 1200 kg/dia |

| Comprimento da fritadeira | 5 - 8 eu |

| Método de aquecimento | Gás, diesel, ou elétrico |

Sistema de secagem em linha de produção de macarrão instantâneo não frito

- Função: Desidrata macarrão usando secagem com ar quente em vez de fritar.

- Especificações Técnicas:

| Parâmetro | Faixa/Especificação |

|---|---|

| Temperatura de secagem | 60 - 80 °C |

| Duração da secagem | 30 - 60 minutos |

| Teor final de umidade | ≤ 12% |

| Tipo de secador | Túnel de ar quente contínuo |

| Capacidade | 100 - 200 pacotes/min |

Transportador de resfriamento em equipamento de produção de macarrão instantâneo

- Função: Estabiliza a temperatura antes de embalar.

- Especificações Técnicas:

| Parâmetro | Faixa/Especificação |

|---|---|

| Tempo de resfriamento | 5 - 10 minutos |

| Comprimento do transportador | 4 - 8 eu |

| Sistema de refrigeração | Circulação de ar forçada |

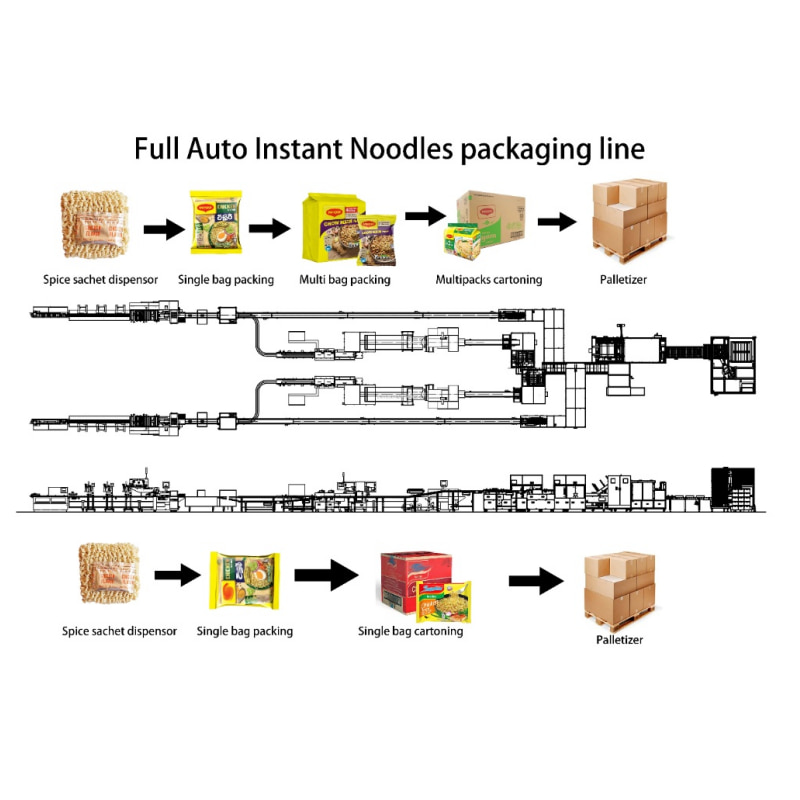

Máquina de embalagem para linha de produção de macarrão instantâneo

- Função: Embala macarrão em sacos selados.

- Especificações Técnicas:

| Parâmetro | Faixa/Especificação |

|---|---|

| Velocidade de embalagem | 80 - 120 pacotes/min |

| Dimensões da bolsa | 70 × 100 mm - 120 × 150 milímetros |

| Tipo de filme | BOPP, BICHO DE ESTIMAÇÃO, laminado |

| Método de vedação | Selagem térmica |

| Sistema de controle | Tela sensível ao toque CLP |

Referência de capacidade da linha de produção de macarrão instantâneo

| Modelo | Capacidade (pacotes/8h) | Poder (KW) | Espaço físico (m²) |

|---|---|---|---|

| Linha Pequena de Macarrão Instantâneo | 50,000 - 80,000 | 80 - 100 | 150 - 200 |

| Linha de Macarrão Instantâneo Médio | 120,000 - 200,000 | 120 - 160 | 250 - 400 |

| Linha Grande de Macarrão Instantâneo | 250,000 - 350,000 | 200 - 250 | 450 - 600 |

| Linha de produção extra grande | 400,000+ | 280 - 350 | 700 - 900 |

Automação e uso de energia na linha de produção de macarrão instantâneo

- Sistemas de controle PLC com IHM touchscreen.

- Inversores de frequência variável para ajuste de rolos e transportadores.

- Sistemas de filtragem e reciclagem de óleo.

- Consumo de energia:

- Vapor: 200 - 400 kg/h

- Eletricidade: 120 - 350 KW

- Óleo (linha frita): 8 - 12% de peso de macarrão

Padrões para linha de produção de macarrão instantâneo

- Certificação CE – para mercados europeus

- ISO 9001:2015 – Sistema de gestão da qualidade

- Conformidade com HACCP – Garantia de segurança alimentar

- Materiais de qualidade alimentar FDA – Para a América do Norte

RFQ - Perguntas frequentes sobre linha de produção de macarrão instantâneo

Q1: Qual é a capacidade de produção da sua linha de produção de macarrão instantâneo?

A1: Oferecemos linhas de produção que vão desde 50,000 pacotes para mais 400,000 pacotes por 8 horas. Pequeno, médio, e linhas de grande escala podem ser personalizadas com base na demanda do mercado.

Q2: Sua linha de produção de macarrão instantâneo pode produzir macarrão frito e não frito?

A2: Sim. Nós fornecemos linhas de macarrão instantâneo frito com fritadeiras contínuas e linhas de macarrão instantâneo não frito com secadores de ar quente. Ambos os tipos podem ser personalizados de acordo com os requisitos da sua receita.

Q3: Qual é o tamanho e o peso típicos do bloco de macarrão instantâneo produzido?

A3: O tamanho padrão do bloco de macarrão é 65–85mm de comprimento com pesos de 60–100g. Esses parâmetros podem ser ajustados de acordo com o seu mercado-alvo.

Q4: Quais matérias-primas são necessárias para a produção?

A4: A principal matéria-prima é farinha de trigo. Ingredientes adicionais incluem água, sal, agentes alcalinos, e temperos opcionais. Nossa linha suporta receitas padrão e formulações personalizadas.

Q5: Quanta energia e vapor a linha de produção de macarrão instantâneo consome?

A5: Dependendo da capacidade:

- Eletricidade: 120 - 350 KW

- Vapor: 200 - 400 kg/h

- Consumo de óleo (para macarrão frito): 8 - 12% de peso de macarrão

Q6: Quais certificações suas máquinas possuem?

A6: Nossos equipamentos estão em conformidade com Certificação CE, ISO 9001:2015, Padrões HACCP, e Requisitos de material de qualidade alimentar da FDA para mercados internacionais.

Q7: Qual é o prazo de entrega de uma linha de produção de macarrão instantâneo?

A7: O prazo de entrega padrão é 60–90 dias dependendo do nível de personalização, tamanho da linha, e quantidade do pedido.

P8: Você fornece serviços de instalação e treinamento?

A8: Sim. Nós oferecemos orientação de instalação no local, treinamento de operadores, e documentação técnica. Suporte técnico remoto também está disponível.

Q9: A máquina de embalagem pode lidar com diferentes tamanhos de sacos?

A9: Sim. Nossa unidade de embalagem suporta 70 × 100 mm até 120 × 150 milímetros tamanhos de bolsa. É compatível com BOPP, BICHO DE ESTIMAÇÃO, e filmes laminados com selagem térmica.

Q10: Quais serviços pós-venda estão disponíveis?

A10: Nós fornecemos garantia de um ano, fornecimento vitalício de peças de reposição, solução de problemas remotos, e serviços opcionais de manutenção no local em todo o mundo.

Escolhendo um fabricante de linha de produção de macarrão instantâneo

O linha de produção de macarrão instantâneo oferece às fábricas de alimentos um sistema confiável e eficiente para produção em larga escala. Examinando as especificações técnicas – capacidade de mistura, largura do rolo, desempenho fumegante, tamanho da fritadeira, e velocidade de embalagem – os compradores podem escolher o modelo certo para suas necessidades.

Seja pequeno, médio, ou em grande escala, uma linha de macarrão instantâneo bem selecionada garante qualidade estável do produto, eficiência energética, e conformidade com os padrões internacionais de segurança alimentar.