Introduction

The Machine to make a tomato It is an essential equipment in the industrial processing of tomatoes, specially designed to produce preserves, Purés, sauces and concentrates with a long shelf life. This type of machine is used in agroindustrial plants, small and medium businesses, and artisanal enterprises that seek to transform fresh tomato into a stable product for commercialization.

This blog covers in detail how to properly operate a tomato canning machine., the technical requirements that must be met and how to perform preventive maintenance to extend its useful life and maintain efficient and safe production.

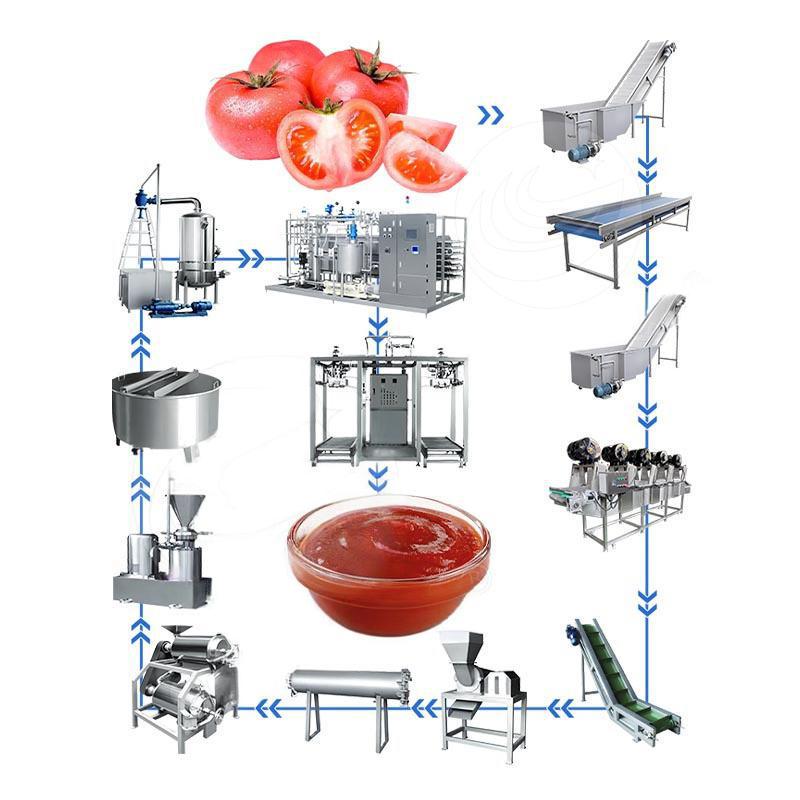

1. Main Components of a Tomato Canning Machine

A canned tomato production line may include:

- Receiving hopper

- Rotary or immersion washing machine

- Manual selection table

- Tomato crusher or grinder

- pulper and refiner

- Evaporator or concentrator (optional for thick pulps)

- mixing tank

- Cooker or pasteurizer

- Automatic packaging (bottles, cans or sachets)

- Storage tank

- Sterilizer

Each component plays a crucial role in the conservation process.

2. Step by Step Operation Process

2.1 Initial Preparation

- Check that the tomato canning machine is clean and in operating condition..

- Make sure electrical and steam/water connections are properly installed.

- Turn on the main system and wait for the equipment to reach operating temperature or pressure.

2.2 Loading and Washing

- Fresh tomatoes are placed in the hopper.

- They are automatically washed in the washing machine with recycled and filtered water.

- They then pass along a conveyor belt to the sorting table where workers remove damaged tomatoes..

2.3 Crushed and pulped

- Tomatoes are crushed with a crushing machine.

- The resulting pulp goes to a pulper/refiner that separates skins and seeds..

2.4 Concentration and Mixing (Optional)

- If it is necessary to concentrate the product, a vacuum evaporator is used.

- You can add salt, sugar or preservatives in the mixing tank.

2.5 Cooking or Pasteurization

- The pulp goes to a cooker or pasteurizer that raises the temperature to 85ºC-95ºC during 5-10 minutes.

- The elimination of bacteria is ensured without damaging the flavor or color.

2.6 Packing

- The hot product is transferred to a packaging machine.

- Can be packaged in glass bottles, cans or stand-up bags.

- Filling is done hot, followed by hermetic closure.

2.7 Final Sterilization

- The filled containers go to a sterilizer.

- If kept at 100ºC for 15-30 minutes depending on volume.

3. Technical Requirements of the Tomato Canning Machine

| Parameter | Standard specification |

|---|---|

| Production capacity | 300 kg/h to 5000 kg/h |

| Manufacturing material | Stainless Steel Food Grade 304/316 |

| Energy source | Three-phase electric 380V, vapor, gas |

| Installed power | 5 kW a 40 kW depending on size |

| Pasteurization temperature | 85ºC – 95ºC |

| Packaging type | glass bottle, if, lata |

| Automation | Manual, semi-automatic or automatic |

4. Operation Recommendations

- Use fresh tomatoes, ripe and without visible damage.

- Clean the system before and after each day.

- Control the temperature at each stage: crushed, cooking, packing.

- Use gloves and personal protective equipment (EPP).

- Constantly monitor pressures and temperatures.

5. Preventive Maintenance

5.1 Daily

- Filter cleaning, hopper, tubes and hoses.

- Checking joints and connections.

5.2 Weekly

- Check engines, straps, temperature sensors.

- Apply lubrication to mechanical points.

5.3 Monthly

- Check electrical resistances and steam system.

- PLC verification, drives and control panel.

5.4 Annually

- Replacement of wearing parts: Valves, bearings.

- General audit by specialized technician.

6. Safety and Regulations

- Comply with local health regulations (HACCP, ISO 22000).

- Use only materials suitable for contact with food.

- Install overtemperature and pressure sensors.

- Have fire extinguishers and emergency showers on hand.

7. Conclusion

A Machine to make a tomato well operated and maintained can guarantee stable productions, safe and high quality. Whether for a small local factory or an industrial plant, understanding its technical operation and applying maintenance protocols is key to long-term success.

For those who want to undertake in the world of agribusiness, This guide serves as an essential technical basis to implement an efficient and profitable canned tomato production line..